Product

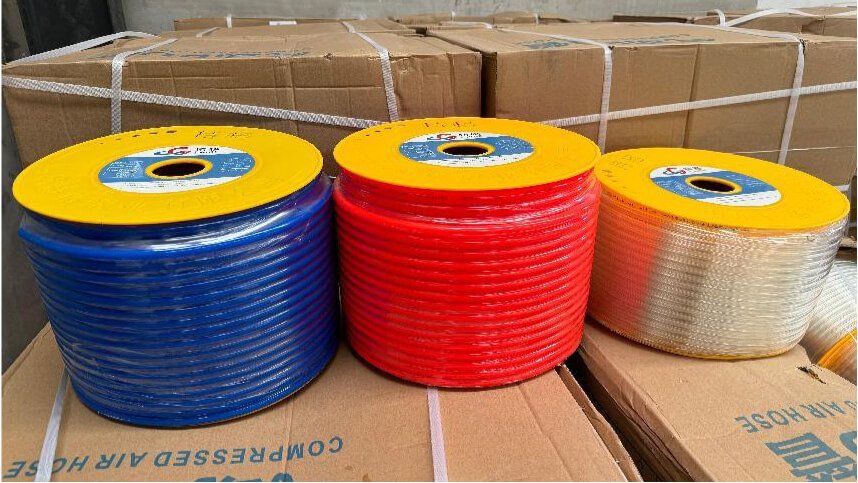

PU tube

PU pipe is a flexible pipe material widely used in pneumatic conveying systems. It has strong wear resistance, flexibility and corrosion resistance, and is especially suitable for transporting various types of dry bulk materials, such as powders, granules, etc.

Principle

The working principle of PU pipe is mainly reflected in its physical characteristics and structural design:

Flexible transmission: PU pipe has excellent flexibility and can be easily bent to adapt to complex installation environments, and the internal circulation area will not be significantly reduced due to bending.

Wear-resistant protection: The inner wall is made of high-strength polyurethane material, which can effectively resist material impact and friction and extend the service life.

Sealing performance: The high-quality joint design ensures the tightness of the connection and prevents gas or material leakage.

Antistatic treatment: Some PU pipes have been specially treated to have antistatic functions, reducing dust accumulation and the risk of explosion. When the high-speed airflow containing solid particles passes through the PU pipe, due to the existence of its wear-resistant inner layer, even if the material hits the pipe wall at a high speed, it is difficult to cause obvious wear to it. In addition, PU pipes can also withstand certain temperature changes and chemical erosion, ensuring long-term stable operation. Parameter

| Usage pressure | 6-10kg/cm² |

| Tear strength | 110kg/cm² |

| Tensile strength | 600kg/cm² |

| Burst pressure | 30kg/cm2 |

| Code No. | Size | Work pressure | Burst pressure 20℃ | Burst pressure 60℃ | bending radius | |||

| L.D. | O.D. | Length | Working pressure | burst pressure | burst pressure | bending radius | ||

| mm | mm | m | kg/c㎡ | kg/c㎡ | kg/c㎡ | mm | ||

| METRIC SYSTEM | IFS-0425 | 2.5 | 4 | 200 | 10 | 38 | 21 | 10 |

| IFS-0640 | 4 | 6 | 200 | 10 | 31 | 17 | 15 | |

| IFS-0850 | 5 | 8 | 100 | 10 | 32 | 19 | 19 | |

| IFS-1065 | 6.5 | 10 | 100 | 10 | 31 | 18 | 25 | |

| IFS-1280 | 8 | 12 | 100 | 10 | 31 | 17 | 37 | |

| IFS-1410 | 10 | 14 | 100 | 8 | 20 | 11 | 56 | |

| IFS-1612 | 12 | 16 | 100 | 8 | 17 | 10 | 60 | |

| IFS-1814 | 14 | 18 | 50 | 8 | 15 | 10 | 65 | |

| IFS-2016 | 16 | 20 | 50 | 8 | 15 | 10 | 70 | |

Features and Advantages

Excellent wear resistance: Polyurethane material has extremely high hardness and wear resistance, can effectively resist material impact and friction, and significantly extend the service life.

Highly flexible: easy to bend and install, adapting to complex and changeable on-site environments without affecting the internal circulation area.

Broad chemical compatibility: good corrosion resistance to a variety of chemicals, suitable for different industrial media.

Excellent anti-aging performance: It can work stably in a wide temperature range and is not easily affected by factors such as ultraviolet rays and ozone.

Low Noise Transmission: Soft structure helps absorb vibration and noise, improving the work environment.

Safe and reliable: Some models are equipped with anti-static functions, which reduces dust accumulation and the risk of explosion.

Easy maintenance: The lightweight design is easy to transport and replace, reducing maintenance costs.

Environmentally friendly: Does not contain lead, cadmium and other harmful substances, and meets environmental protection standards. Usage Scenarios

PU pipes are widely used in all aspects of pneumatic conveying systems, especially where large amounts of powder or granular materials need to be transported over long distances and at high lifts.