Product

Oxidation blower

The oxidation Roots blower is a special purpose Roots blower designed specifically for promoting or controlling the oxidation process in chemical reactions.

Principle

The working principle of the oxidation Roots blower is similar to other types of Roots blowers, that is, a pair of synchronized gears drive two "8"-shaped three-bladed rotors to rotate in the cylinder without direct contact. As the rotors rotate, multiple sealed working volumes are formed between them. These volumes in turn suck in gas from the air inlet, compress it in the closed space, and then discharge it from the exhaust port. In order to adapt to the needs of the oxidation process, the oxidation Roots blower may be equipped with additional functions, such as a preheating system to increase the temperature of the oxygen before entering the reactor, or the use of special materials and coatings to enhance the equipment's resistance to harsh working conditions (such as high temperatures). , high pressure, corrosive environment) resistance.

Parameter

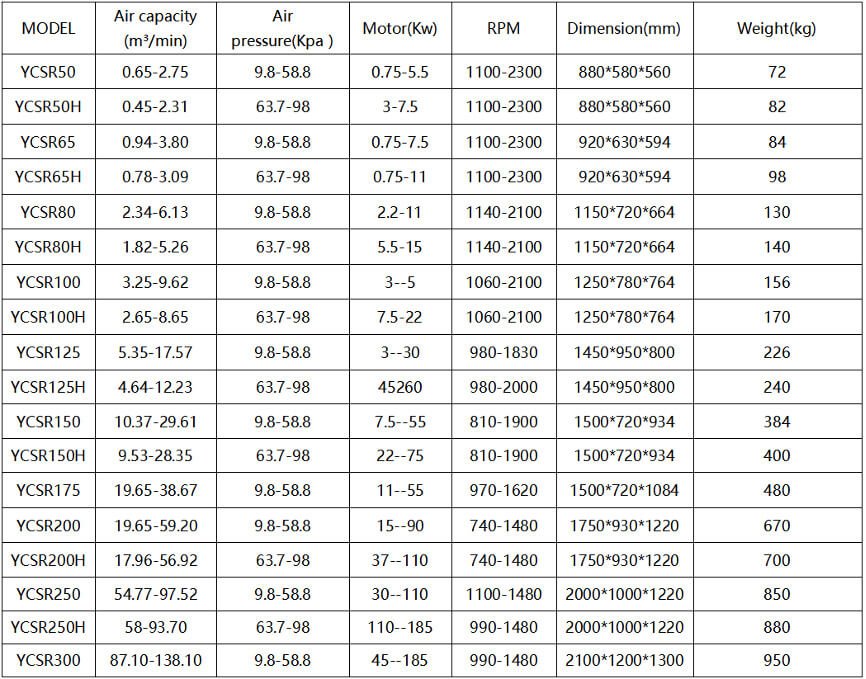

Single fuel tank: YCSR-(50/65/80/100/125/150/175/200/250/300)

High-pressure double fuel tank: YCSR-(80/100/125/150/200/250/300)H

Intensive: YCSR-MJ(50/65/80/100/125/150/175/200/250)

Roots vacuum pump: YCSR-(80/100/125/150/200/250/300)V

Features and Advantages

High temperature resistance: Made of high temperature resistant materials to ensure long-term stable operation in high temperature environments; some models are also equipped with a cooling system to further protect key components from overheating.

Strong corrosion resistance: For corrosive gases that may appear during the oxidation process, anti-corrosion coatings are used or alloy materials with natural anti-corrosion properties are selected.

High reliability: Optimized design reduces maintenance requirements and extends service life; at the same time, the internal structure is sturdy and durable, and can effectively resist the impact of dust and other impurities.

High efficiency and energy saving: The advanced rotor design improves volumetric efficiency and reduces energy consumption; in addition, operating parameters can be adjusted according to actual working conditions to achieve optimal energy conversion.Precise control: Equipped with an advanced control system, the pressure and flow rate of the output gas can be accurately adjusted to ensure that the requirements of different process stages are met.

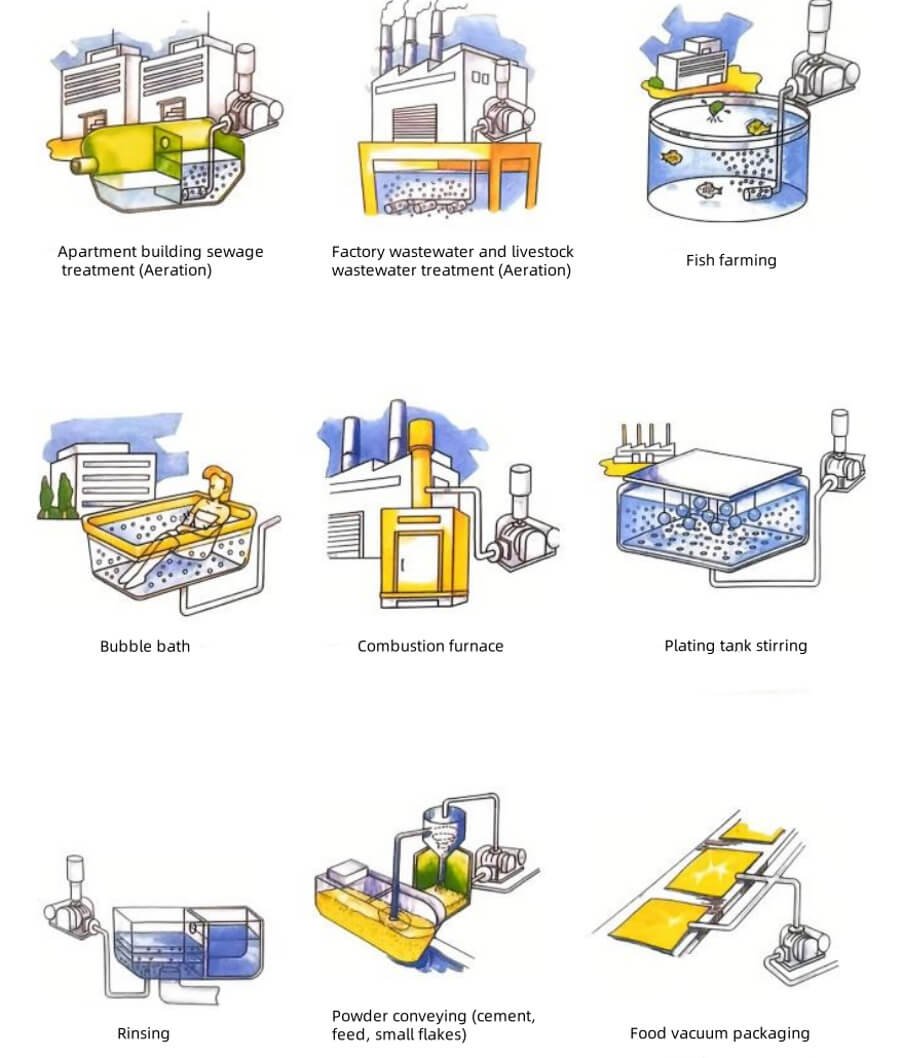

Strong adaptability: Whether processing traditional chemical raw materials or emerging environmentally friendly materials, oxidation Roots blowers can flexibly cope with different input material types and operating conditions. Usage Scenarios

Oxidation Roots blowers play an important role in many fields due to their unique performance characteristics, and are especially suitable for the following application scenarios: Steel industry: used in the sintering process in iron smelting plants to provide sufficient oxygen to the sinter material layer to accelerate fuel combustion and improve the quality of sinter; it can also be used for the redox reaction in the direct reduced iron (DRI) process.

Chemical industry: Pressurized transportation of gases required for various chemical reactions, such as the recovery and reuse of carbon dioxide in the production of ammonia and methanol; especially for those processes that rely on oxidation reactions, such as nitric acid manufacturing, oxidative synthesis of organic compounds, etc.

Oil and gas processing: used as a secondary air source in catalytic cracking units to help maintain appropriate oxygen concentration to ensure the regeneration effect on the catalyst surface; also used in sulfur recovery units (SRU) to promote the conversion of sulfur dioxide into elemental sulfur.Environmental protection: In exhaust gas treatment facilities, such as flue gas denitration systems in coal-fired power plants, the oxygen provided by the oxidation Roots blower helps convert nitrogen oxides (NOx) into forms that are easier to remove; similarly, in volatile organic It can increase combustion efficiency and reduce harmful emissions in VOCs incinerators.Other industrial applications: including but not limited to kiln ventilation in cement production, furnace oxygen supply in glass manufacturing, etc., all of which rely on a stable supply of oxygen to ensure the smooth progress of the production process.