Product

Return fan

The return fan is used in circulating fluidized bed boilers or other similar equipment to return incompletely burned materials back to the combustion chamber to continue participating in the reaction.

Principle

The working principle of the return Roots blower is based on the standard Roots blower, which uses two three-blade rotors that are not in contact with each other but rotate synchronously to form a series of sealed working volumes in the cylinder. As the rotor rotates, these volumes sequentially suck in gas from the air inlet, compress it in the enclosed space, and then discharge it from the exhaust port. In order to adapt to the needs of the return process, this type of blower is usually equipped with special wear-resistant materials and efficient sealing systems to prevent dust from entering bearings and other key components; at the same time, it may also include preheating or cooling devices to adjust the gas temperature. Ensure optimal operating conditions.

Parameter

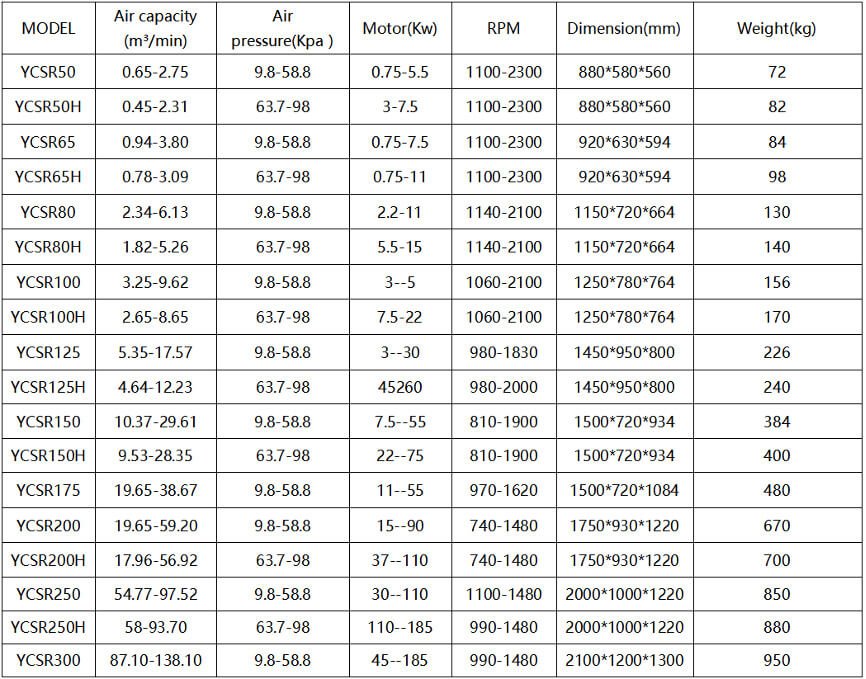

Single fuel tank: YCSR-(50/65/80/100/125/150/175/200/250/300)

High-pressure double fuel tank: YCSR-(80/100/125/150/200/250/300)H

Intensive: YCSR-MJ(50/65/80/100/125/150/175/200/250)

Roots vacuum pump: YCSR-(80/100/125/150/200/250/300)V

Features and Advantages

High temperature resistance: Made of high temperature resistant materials to ensure long-term stable operation in high temperature environments; some models are also equipped with a cooling system to further protect key components from overheating.

Strong wear resistance: In response to the high concentration of dust that may occur during the return process, wear-resistant materials and special sealing technology are used, reducing maintenance requirements and extending service life.

High reliability: Optimized design reduces maintenance requirements and extends service life; at the same time, the internal structure is sturdy and durable, and can effectively resist the impact of dust and other impurities.

High efficiency and energy saving: The advanced rotor design improves volumetric efficiency and reduces energy consumption; in addition, operating parameters can be adjusted according to actual working conditions to achieve optimal energy conversion.Precise control: Equipped with an advanced control system, the pressure and flow rate of the output gas can be accurately adjusted to ensure that the requirements of different process stages are met.

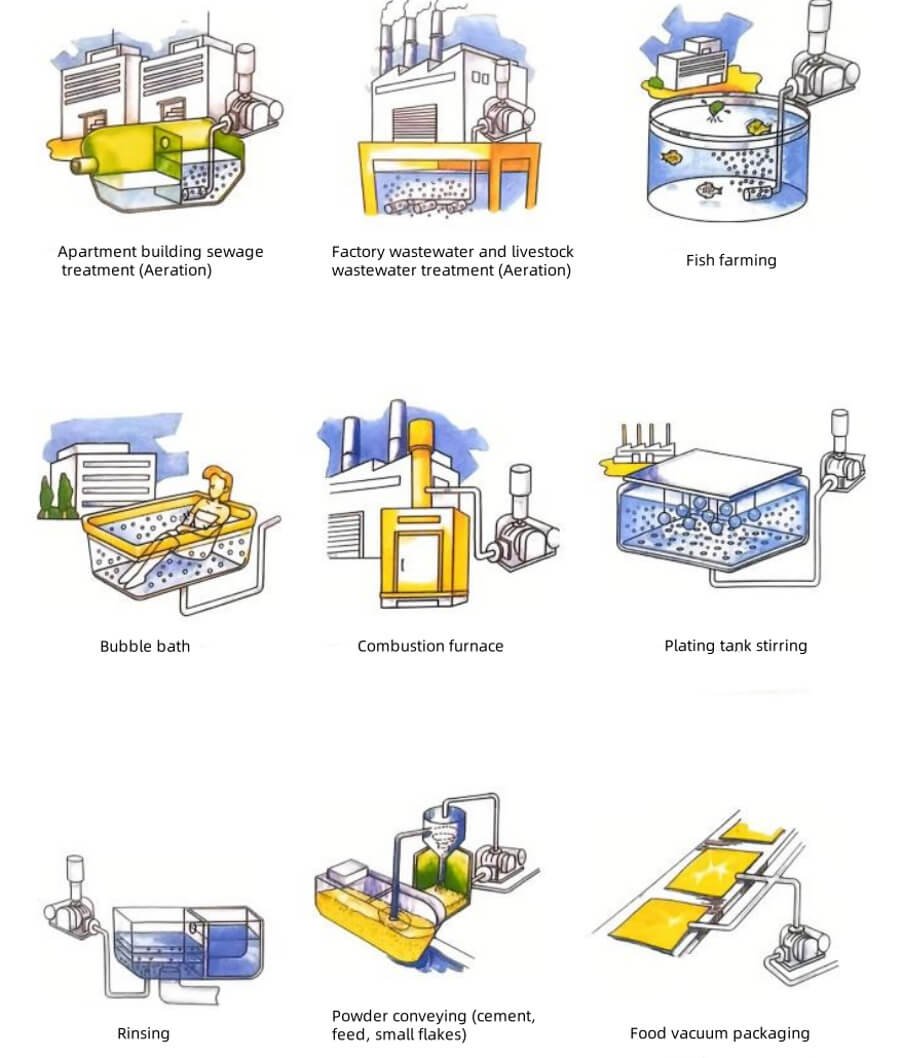

Adaptable: Whether processing traditional fossil fuels or emerging renewable energy sources such as biomass, return roots blowers are flexible enough to handle different input material types and operating conditions. Usage Scenarios

Return Roots blowers play an important role in many fields due to their unique performance characteristics, and are especially suitable for the following application scenarios: Circulating fluidized bed boiler (CFB boiler): This is one of the most typical applications of return Roots blowers. By providing sufficient pressure into the combustion chamber, unburned materials or fly ash can be smoothly returned to the combustion zone, thereby improving fuel combustion efficiency and reducing particulate matter content in emissions.Industrial furnaces: such as cement kilns, lime kilns, etc. In these equipment, the return Roots blower is used to re-send the collected fine powder or unreacted raw materials into the furnace to continue to participate in the reaction, which improves resource utilization.Biomass gasification device: used to reintroduce incompletely converted biomass residue into the gasification furnace to increase gasification efficiency and gas production.

Waste-to-energy plants: Help maintain proper combustion conditions to ensure waste is fully burned while reducing environmental impact.

Metallurgical industry: For example, in the direct reduced iron (DRI) process, the return roots blower can return the incompletely reduced iron oxide particles back to the reactor to improve metal recovery rate and product quality.