Product

Blower used in chemical industry

The Roots blower used in the chemical industry is a volumetric fan specially designed for gas transportation, compression and ventilation needs in the chemical production process.

Principle

The Roots blower used in the chemical industry is a volumetric fan specially designed for gas transportation, compression and ventilation needs in the chemical production process. This type of blower can provide stable and large-flow gas output, and can operate reliably under harsh working conditions such as high temperature, high pressure, and corrosive media. They are widely used in multiple chemical process links such as ammonia synthesis, methanol production, waste gas treatment, and material handling, and are crucial to ensuring the continuity and safety of chemical production.

Parameter

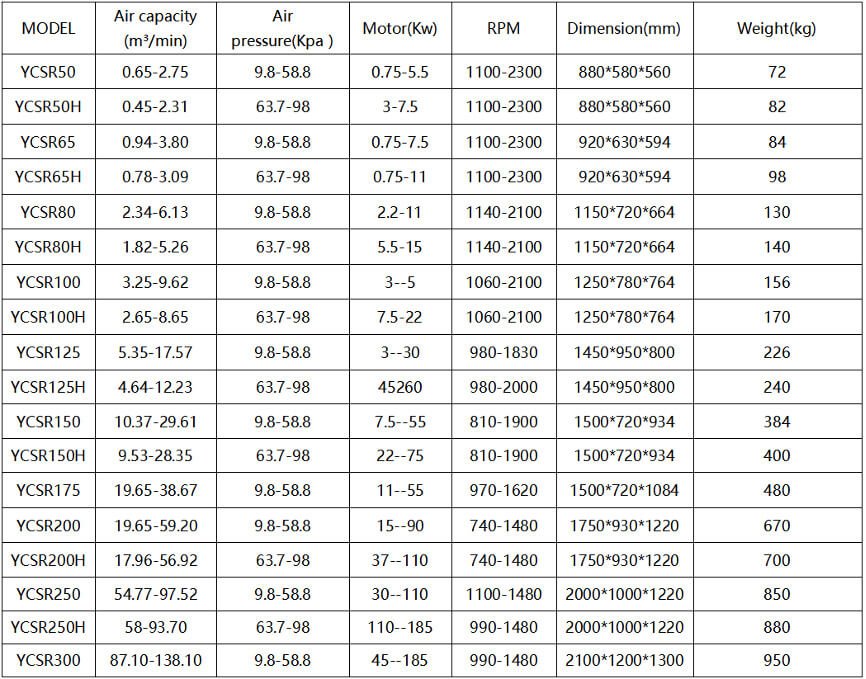

Single fuel tank: YCSR-(50/65/80/100/125/150/175/200/250/300)

High-pressure double fuel tank: YCSR-(80/100/125/150/200/250/300)H

Intensive: YCSR-MJ(50/65/80/100/125/150/175/200/250)

Roots vacuum pump: YCSR-(80/100/125/150/200/250/300)V

Features and Advantages

Excellent corrosion resistance: Made of corrosion-resistant materials, ensuring excellent sealing even when handling corrosive gases.

High efficiency and energy saving: Despite the addition of protective measures, Roots blowers used in the chemical industry still maintain high volume utilization and volumetric efficiency through optimized design, which can reduce energy consumption while ensuring performance.

Low noise: Due to the use of three-blade rotor design and advanced sealing technology, the vibration and noise generated during operation are low.

No internal lubrication required: There are no friction parts inside, so there is no need to use lubricating oil, which reduces maintenance costs and avoids the risk of oil contamination.Long life: High-quality seals can maintain a good sealing state for a long time, extending the service life of the entire equipment.

Cleaning process: It is very suitable for applications that need to transport clean, oil-free compressed air or other gases, such as fine chemicals, pharmaceutical intermediates and other fields.

Compact structure: The overall design is compact, easy to install and arrange, while reducing the floor space.

Easy to maintain: Although the sealing system is relatively complex, due to its high reliability and durability, actual maintenance requirements are less. Daily maintenance mainly includes checking the status of the seals and replacing worn parts. Usage Scenarios

Roots blowers used in the chemical industry play an important role in many fields because of their unique performance characteristics. They are especially suitable for the following application scenarios: Synthetic ammonia and methanol production: used for carbon dioxide recovery and reuse, returning the CO₂ in the reaction tail gas back to the synthesis tower to improve raw material utilization.

Exhaust gas treatment: Participate in the pressurized transportation of gases in exhaust gas purification systems, such as catalytic oxidation devices, adsorption towers, etc., to help remove volatile organic compounds (VOCs) and other harmful gases.

Wastewater treatment: As the power source of the aeration system, it supplies oxygen to the bottom of the sewage treatment tank, promotes microorganisms to decompose organic pollutants, and accelerates the water purification process.

Material handling: As a gas source in a pneumatic conveying system, it is responsible for transporting powdery or granular materials from one place to another through pipelines, such as catalysts, plastic particles, etc.Chemical reaction gas pressurization: Provide necessary pressure conditions for specific chemical reactions, such as hydrogen compression, chlorine gas transportation, etc., to ensure the smooth progress of the reaction.

Vacuum dehydration: used for vacuuming operations of filters or centrifuges to speed up solid-liquid separation and improve production efficiency.

Direct reduced iron (DRI) process: supports the redox reaction in the direct reduced iron process, improves product quality and reduces production costs.

Other industrial applications: including but not limited to various gas treatment tasks in petrochemical, dye and pigment, pesticide and fertilizer industries. In summary, Roots blowers used in the chemical industry are promoting the development of the chemical industry with their excellent technical performance and wide applicability.