Product

Blower used in the food industry

Roots blowers used in the food industry are specialized equipment designed to meet the gas handling tasks required during food processing and production. This type of blower plays a vital role in ensuring food safety, hygienic conditions and efficient production. It is widely used in many process links such as pneumatic conveying, vacuum packaging, and gas control during fermentation. Not only do they need to provide efficient and stable performance, they must also meet strict food safety standards and be able to operate in a clean, oil-free environment.

Principle

The working principle of the Roots blower used in the food industry is to use two three-bladed rotors that do not contact each other but rotate synchronously to form a series of sealed working volumes in the cylinder. As the rotor rotates, these volumes in turn suck in air or gas from the air inlet, compress it in a closed space, and then discharge it from the exhaust port and transport it to where it is needed through the piping system.

Parameter

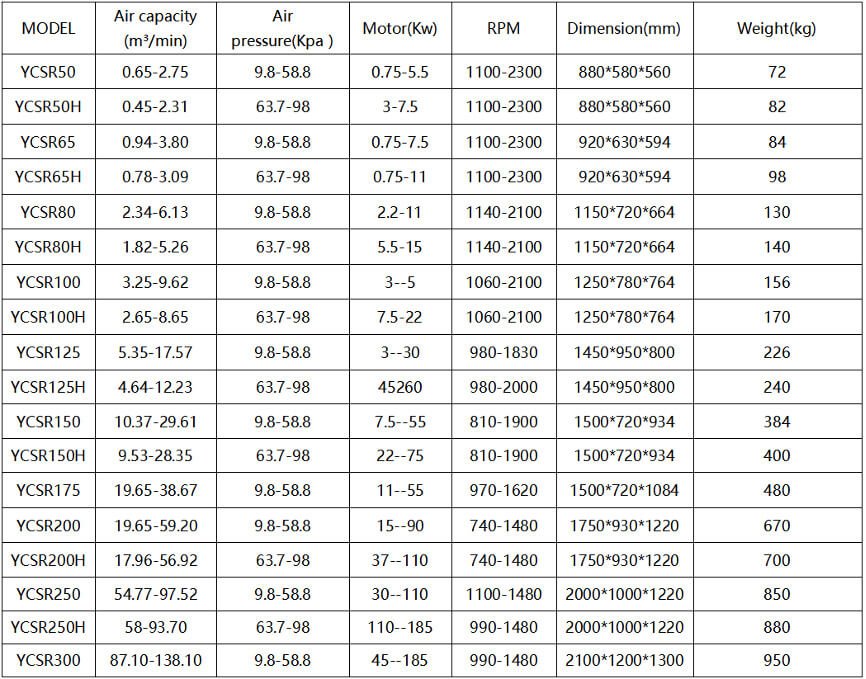

Single fuel tank: YCSR-(50/65/80/100/125/150/175/200/250/300)

High-pressure double fuel tank: YCSR-(80/100/125/150/200/250/300)H

Intensive: YCSR-MJ(50/65/80/100/125/150/175/200/250)

Roots vacuum pump: YCSR-(80/100/125/150/200/250/300)V

Features and Advantages

Oil-free compression to ensure food safety: Oil-free compression technology is adopted to ensure that the output gas is absolutely pure and will not cause any form of contamination to food.

High efficiency and energy saving: Despite the addition of protective measures, through optimized design, the Roots blower for food still maintains high volume utilization and volume efficiency, which can reduce energy consumption while ensuring performance.

Low noise and vibration: Due to the use of three-blade rotor design and advanced sealing technology, the vibration and noise generated during operation are lower, providing a quieter working environment.

Easy to clean and maintain: The overall design is compact, easy to install and arrange, while reducing the floor space; and easy to disassemble and clean, reducing daily maintenance costs.Long life and high reliability: High-quality materials and manufacturing processes ensure long-term reliable operation of the equipment. Daily maintenance mainly includes checking the status of seals and replacing worn parts.

Comply with food safety standards: Strictly follow international food safety standards (such as FDA, CE certification) to ensure that all parts in contact with food use safe materials.

Strong flexibility: the output parameters can be adjusted according to different process requirements and adapted to various gas processing tasks. Usage Scenarios

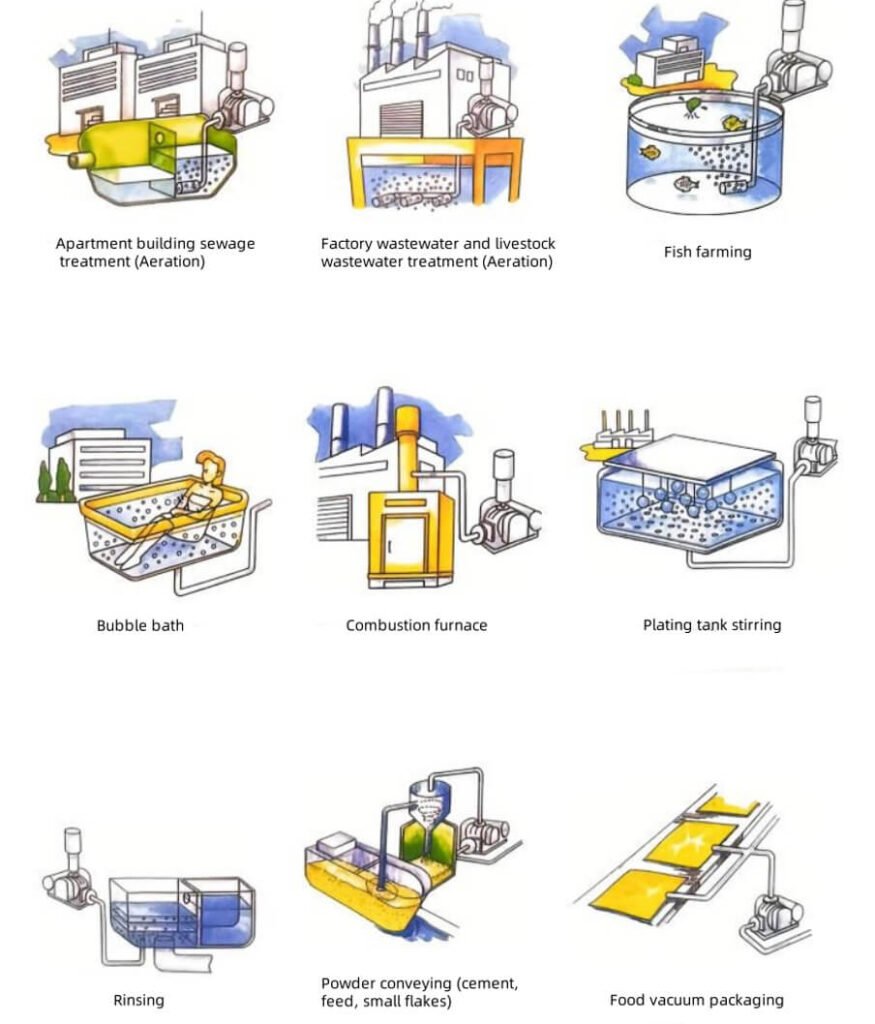

Pneumatic conveying: used to convey powdery or granular materials (such as flour, powdered sugar, coffee beans, etc.) from one place to another through pipelines, improving production efficiency and reducing manual handling.

Vacuum packaging: Participate in the operation of the vacuum packaging machine to provide the necessary vacuum degree to ensure that the air in the food packaging is completely extracted and extend the shelf life.

Fermentation control: In fermentation processes such as beer brewing and yogurt production, it is used to accurately control the supply of carbon dioxide or other gases to maintain an ideal fermentation environment.

Drying and cooling: used in spray drying towers or fluidized bed dryers to provide the necessary ventilation, accelerate water evaporation, and help cool the product.

Controlled atmosphere preservation: In cold storage or transportation vehicles, it is used to adjust gas composition, create a microenvironment conducive to food preservation, and slow down the rate of spoilage.Cleaning and disinfection: Participate in the CIP (cleaning in place) system to provide high-pressure gas for purging and cleaning of pipelines and equipment to ensure sanitary conditions.

Other applications: including but not limited to various gas treatment tasks in dust removal, dehumidification and other fields on food processing lines.