Product

roots blower impeller

The Roots blower impeller (also known as the rotor or blade) is one of the core components of the Roots blower and is responsible for the suction, compression and discharge of gas. This type of blower is usually equipped with two or more trilobal or drum-shaped rotors, which rotate synchronously in the cylinder and complete the gas delivery task through volume changes. The design and manufacturing quality of Roots blower impeller directly affect the efficiency, stability and service life of the equipment.

Principle

The main function of the Roots blower impeller is to achieve the suction, compression and discharge of gas through volume changes. The specific working process is as follows: Gas Intake: As the rotor rotates, a series of sealed working volumes are formed between its blades and the cylinder wall. As the rotor rotates, these volumes gradually expand from the air inlet side, sucking in outside air or other gases.

Gas Compression: As the rotor continues to rotate, the above volume begins to decrease, forcing the gas inside to be compressed. At this time, the pressure of the gas gradually increases.

Gas Exhaust: Eventually, these volumes move to the exhaust port side and open completely, allowing the high-pressure gas to be expelled. During the entire process, the two rotors always rotate in opposite directions synchronously to ensure there is no direct contact. Parameter

| Speed | 2800r/min |

| Voltage | 380V |

| Air volume | 1050m/h |

| Boost | 40kPa |

| Airflow direction | vortex |

| Type | High pressure blower |

| Material | Aluminum alloy |

| Use | Duct fan |

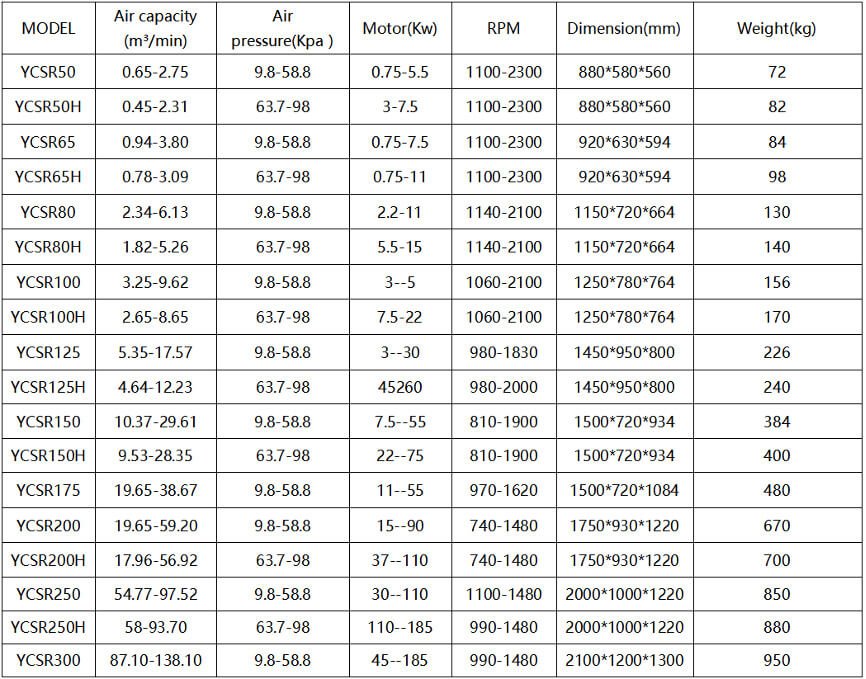

Single fuel tank: YCSR-(50/65/80/100/125/150/175/200/250/300)

High-pressure double fuel tank: YCSR-(80/100/125/150/200/250/300)H

Intensive: YCSR-MJ(50/65/80/100/125/150/175/200/250)

Roots vacuum pump: YCSR-(80/100/125/150/200/250/300)V

Features and Advantages

High volumetric efficiency: Through optimized design and precision manufacturing, the Roots blower impeller can provide high volumetric efficiency and ensure stable gas output.

Low-noise operation: High-quality impeller design and material selection can significantly reduce operating noise and provide a quieter working environment.

Long life and durability: The impeller is made of high-quality materials and undergoes strict heat treatment, which makes the impeller have high strength and wear resistance and extends its service life.

Easy maintenance: Good lubrication conditions and sealing measures reduce the need for routine maintenance and reduce operating costs.

Reliable synchronization: Precise gear coordination ensures synchronous rotation of the rotors, avoiding the risk of failure caused by out-of-synchronization.

Strong adaptability: According to the requirements of different application scenarios, the size, shape and material of the impeller can be adjusted to meet specific process needs. Usage Scenarios

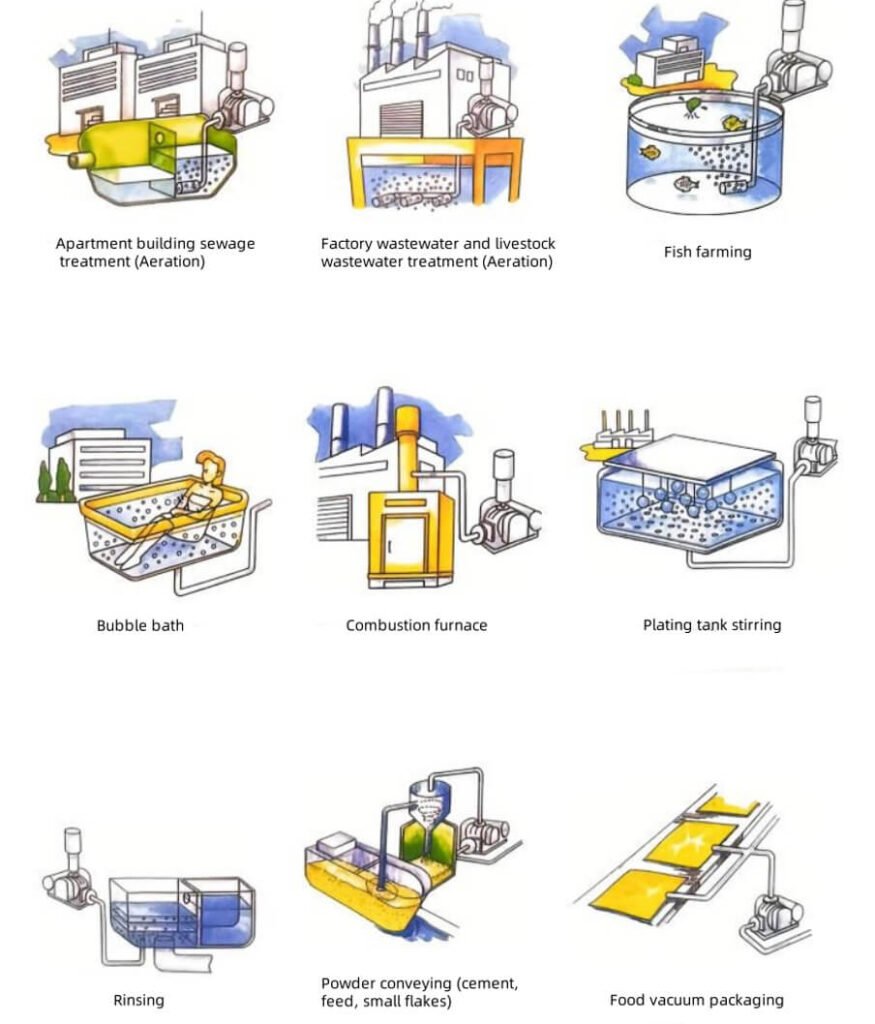

Widely used in gas transportation and pressurization in sewage treatment (such as aeration), chemical industry, food processing, pharmaceutical and other industries.