Product

Blower used in cement industry

Roots blowers used in the cement industry are special equipment designed for tasks such as gas transportation, ventilation and material handling in the cement production process. This type of blower plays a vital role in cement plants and is used in many process links such as kiln ventilation, raw meal grinding, clinker cooling, waste gas treatment, etc. They not only need to have efficient and stable performance, but also must be able to adapt to harsh working conditions such as high temperature, high pressure, large dust content, and corrosive media.

Principle

The working principle of the Roots blower used in the cement industry is to use two three-bladed rotors that do not contact each other but rotate synchronously to form a series of sealed working volumes in the cylinder. As the rotor rotates, these volumes sequentially suck in gas from the air inlet, compress it in the enclosed space, and then discharge it from the exhaust port.

Parameter

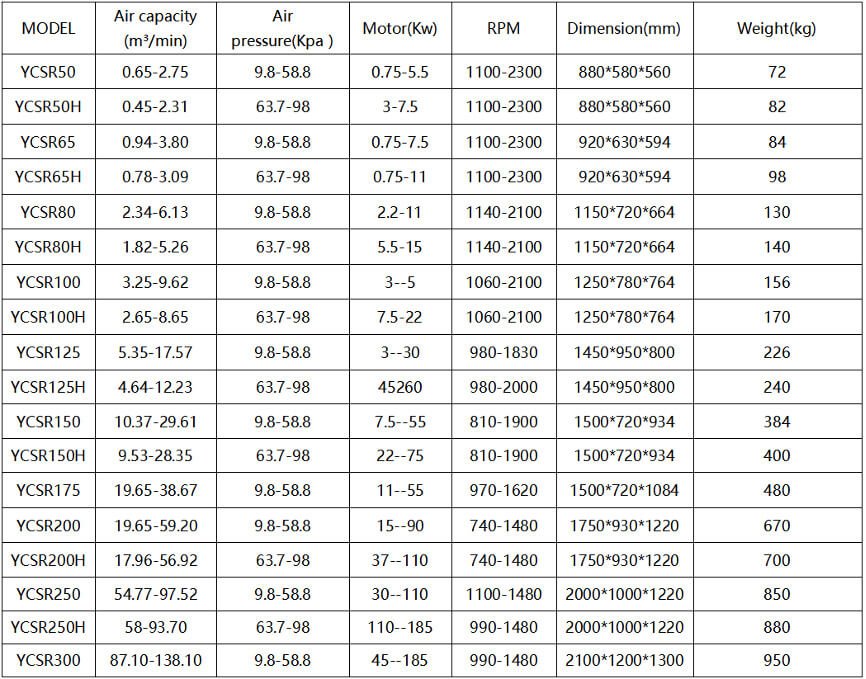

Single fuel tank: YCSR-(50/65/80/100/125/150/175/200/250/300)

High-pressure double fuel tank: YCSR-(80/100/125/150/200/250/300)H

Intensive: YCSR-MJ(50/65/80/100/125/150/175/200/250)

Roots vacuum pump: YCSR-(80/100/125/150/200/250/300)V

Features and Advantages

Excellent high temperature and high pressure resistance: Made of high temperature resistant materials to ensure long-term stable operation even under extreme conditions.

Efficient gas processing capability: The pressure and flow rate of the output gas can be adjusted within a wide range to ensure smooth process flow.

Low noise and vibration: Using a three-blade rotor design and advanced sealing technology, the vibration and noise generated during operation are lower, providing a quieter working environment.

No internal lubrication required: There are no friction parts inside, so there is no need to use lubricating oil, which reduces maintenance costs and avoids the risk of oil contamination.Long life and low maintenance: High-quality materials and manufacturing processes ensure long-term reliable operation of the equipment. Daily maintenance mainly includes checking the status of seals and replacing worn parts.

Compact structure: The overall design is compact, easy to install and arrange, while reducing the floor space.

Strong flexibility: the output parameters can be adjusted according to different process requirements and adapted to various gas processing tasks. Usage Scenarios

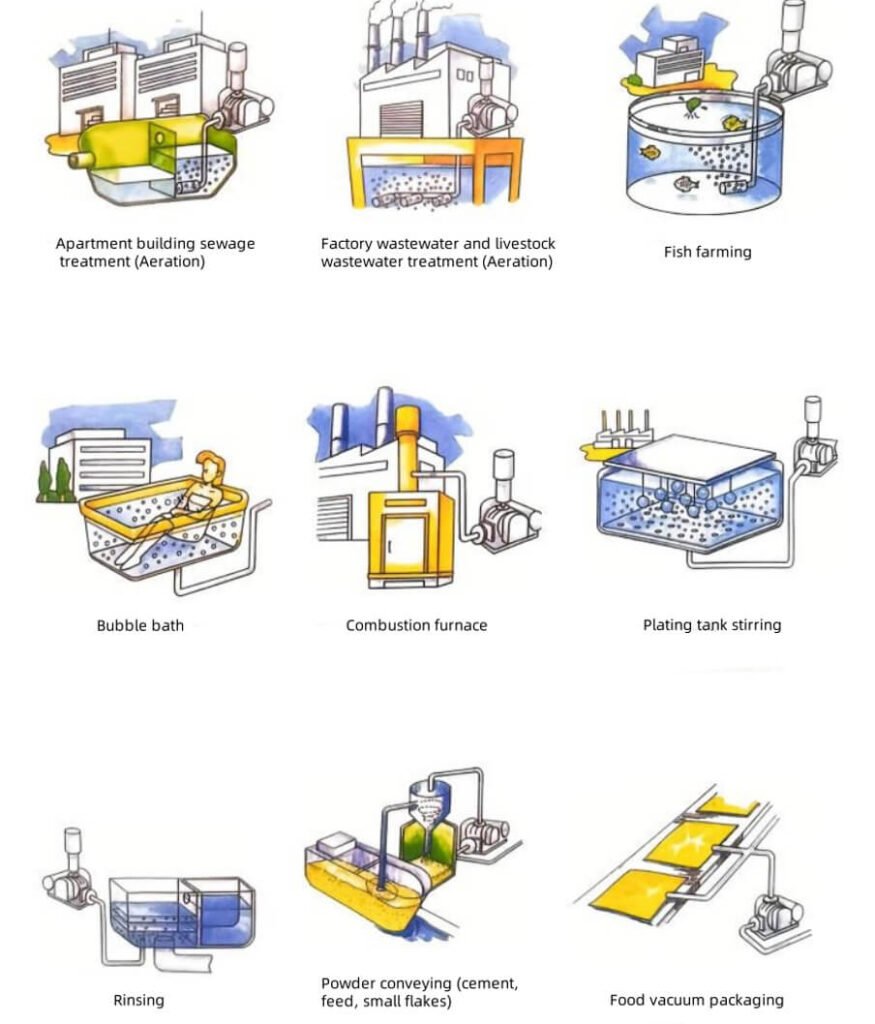

Roots blowers used in the cement industry play an important role in many fields because of their unique performance characteristics. They are especially suitable for the following application scenarios: Kiln ventilation: As a key component of rotary kilns and other calcining equipment, it provides the necessary air supply to ensure proper combustion conditions, improve product quality and reduce environmental pollution.

Raw meal grinding: Participates in the gas transportation during the raw meal preparation process, helps maintain the negative pressure state of the grinding system, prevents dust from overflowing, and improves the working environment.

Clinker cooling: used in grate coolers or other cooling devices to quickly remove heat, accelerate the clinker cooling process, and improve the efficiency of subsequent processes.

Exhaust gas treatment: Participate in exhaust gas purification systems, such as electrostatic precipitators, bag dust collectors, etc., to help remove particulate matter and other harmful substances in flue gas and ensure that emissions comply with environmental standards.

Material handling: As a gas source in a pneumatic conveying system, it is responsible for transporting powdery or granular materials from one place to another through pipelines, such as limestone, coal powder, etc.Other industrial applications: including but not limited to various gas treatment tasks in the fields of secondary air supply and tertiary air circulation of precalciner systems.