Product

Fans used in the power industry

Roots blowers used in the power industry are specialized equipment designed for the gas handling tasks required during the production and transmission of electricity. This type of blowers plays a vital role in thermal power plants, nuclear power plants, and renewable energy power generation facilities (such as biomass power generation), and is used in key applications such as flue gas desulfurization (FGD), boiler ventilation, fuel transportation, exhaust gas treatment, etc. process link. They not only need to have efficient and stable performance, but also must be able to adapt to harsh working conditions such as high temperature, high pressure, and corrosive media.

Principle

The Roots blower used in the electric power industry uses two three-bladed rotors that do not contact each other but rotate synchronously to form a series of sealed working volumes in the cylinder. As the rotor rotates, these volumes sequentially suck in gas from the air inlet, compress it in the enclosed space, and then discharge it from the exhaust port.

Parameter

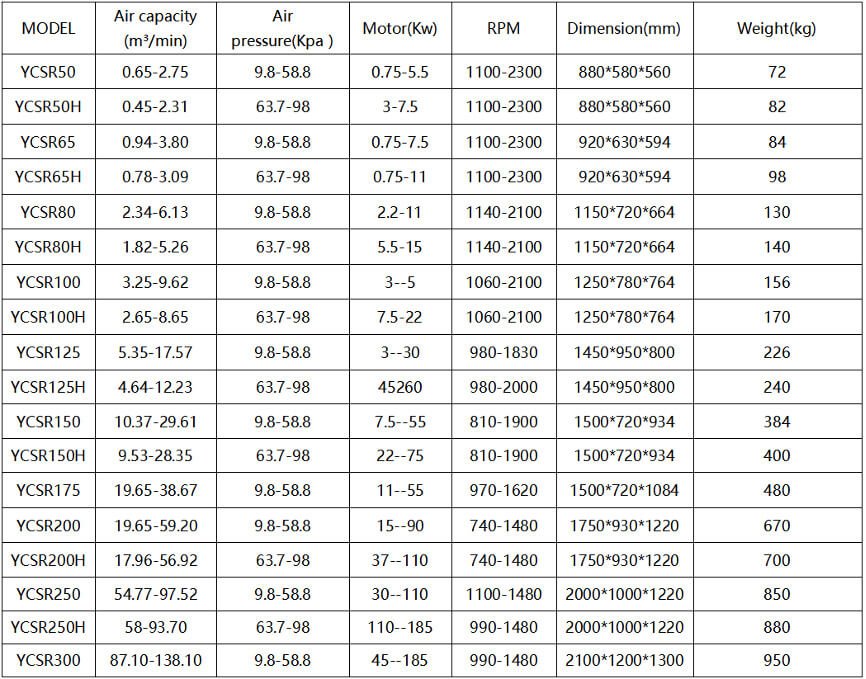

Single fuel tank: YCSR-(50/65/80/100/125/150/175/200/250/300)

High-pressure double fuel tank: YCSR-(80/100/125/150/200/250/300)H

Intensive: YCSR-MJ(50/65/80/100/125/150/175/200/250)

Roots vacuum pump: YCSR-(80/100/125/150/200/250/300)V

Features and Advantages

Excellent high temperature and high pressure resistance: Made of high temperature resistant materials to ensure long-term stable operation even under extreme conditions.

Efficient gas processing capability: The pressure and flow rate of the output gas can be adjusted within a wide range to ensure smooth process flow.

Low noise and vibration: Using a three-blade rotor design and advanced sealing technology, the vibration and noise generated during operation are lower, providing a quieter working environment.

No internal lubrication required: There are no friction parts inside, so there is no need to use lubricating oil, which reduces maintenance costs and avoids the risk of oil contamination.Long life and low maintenance: High-quality materials and manufacturing processes ensure long-term reliable operation of the equipment. Daily maintenance mainly includes checking the status of seals and replacing worn parts.

Compact structure: The overall design is compact, easy to install and arrange, while reducing the floor space.

Strong flexibility: the output parameters can be adjusted according to different process requirements and adapted to various gas processing tasks.

Environmentally friendly: By providing a clean, non-polluting gas source, it helps reduce pollutant emissions and promotes the development of green energy. Usage Scenarios

Roots blowers used in the power industry play an important role in many fields due to their unique performance characteristics, and are especially suitable for the following application scenarios:Flue gas desulfurization (FGD) system: used in the flue gas purification process of coal-fired power plants to help remove pollutants such as sulfur dioxide and achieve a cleaner way of producing electricity.

Boiler ventilation: serves as the air supply source for the combustion chamber to ensure proper oxygen concentration, improve combustion efficiency and reduce incomplete combustion products.

Fuel transportation: Participate in the pneumatic transportation system of coal or other solid fuels to transport fuel from the storage area to the boiler room to ensure continuous and stable fuel supply.

Exhaust gas treatment: used in exhaust gas treatment devices, such as volatile organic compounds (VOCs) incinerators, ozone decomposition reactors, etc., to ensure that emissions comply with environmental standards.

Cooling tower ventilation: Provide the necessary ventilation volume for the cooling tower, maintain appropriate water temperature and heat exchange efficiency, and ensure the normal operation of the generator set.Direct reduced iron (DRI) process: In some new steel production processes, it is used to provide the necessary gas pressure to support the redox reaction.

Biomass power generation: Helps maintain proper combustion conditions to ensure waste is fully burned while reducing environmental impact.

Other industrial applications: including but not limited to various gas treatment tasks in waste incineration power generation, geothermal power generation and other fields.