Product

High pressure Roots blower

High-pressure Roots blowers are a special form of Roots blowers designed to produce higher gas pressures. In the industry, Roots blowers with a pressure boost value greater than 49KPa are usually classified as high-pressure Roots blowers. This type of blower increases the air compression inside the air chamber by optimizing the internal structure, strengthening the rotor group, increasing the volume, increasing the rotation speed, and adjusting the impeller clearance, thereby achieving higher output pressure. They are widely used in a variety of industrial environments where high pressure transport or compressed gas is required.

Principle

The basic working principle of the high-pressure Roots blower is the same as other types of Roots blowers, that is, two rotors that are not in contact with each other but rotate synchronously are used to form a series of sealed working volumes, and are sucked in from the air inlet as the rotors rotate. The gas is compressed in a closed space and finally discharged from the exhaust port. However, in order to adapt to higher working pressure, the high-pressure Roots blower adopts a special sealing mechanism to prevent bearing lubricating oil and gear lubricating oil from flowing into the interior of the casing, ensuring the cleanliness of the output medium. Additionally, its design allows for stable airflow output at higher pressures.

Parameter

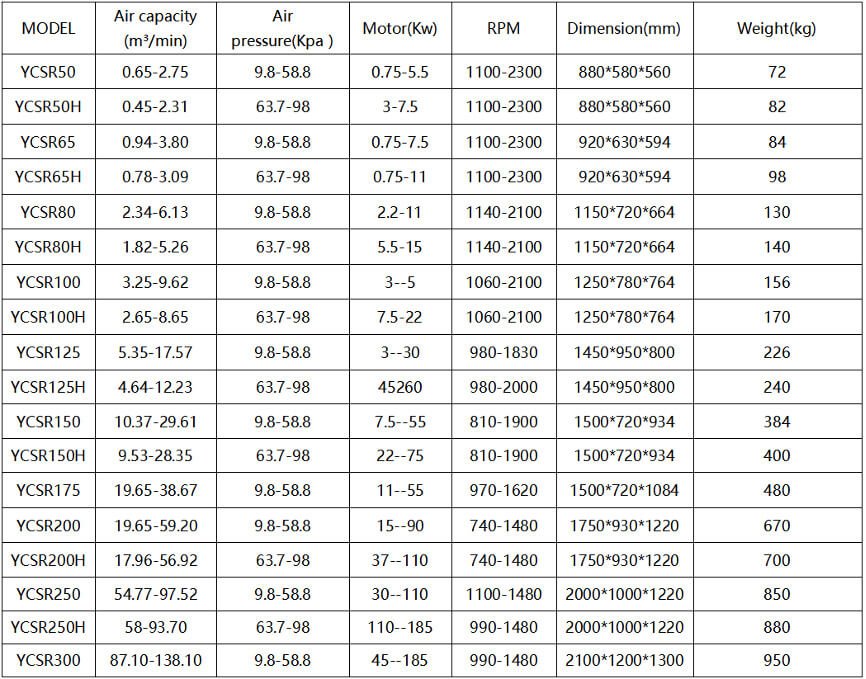

Single fuel tank: YCSR-(50/65/80/100/125/150/175/200/250/300)

High-pressure double fuel tank: YCSR-(80/100/125/150/200/250/300)H

Intensive: YCSR-MJ(50/65/80/100/125/150/175/200/250)

Roots vacuum pump: YCSR-(80/100/125/150/200/250/300)V

Features and Advantages

Strong pressure boosting ability: able to provide outlet pressure significantly higher than that of ordinary Roots blowers, suitable for applications requiring high

Pressure application scenarios.

Bidirectional function: it can be used as both suction and blowing, increasing the application flexibility of the equipment.

Oil-free lubrication: No oil lubrication is required inside the casing, ensuring the purity of the output medium. It is especially suitable for occasions with strict requirements on gas purity.

Efficient and stable: It can maintain stable air flow output even under high-pressure conditions, improving work efficiency and reliability.Easy maintenance: Since there is no direct contact between the rotors, wear is reduced and maintenance requirements are reduced.

Strong environmental adaptability: It can work normally under different temperatures (usually below 40°C) and humidity (relative humidity below 80%), and is also capable of transporting corrosive components or flammable gases containing acids and alkalis. A certain tolerance.Usage Scenarios

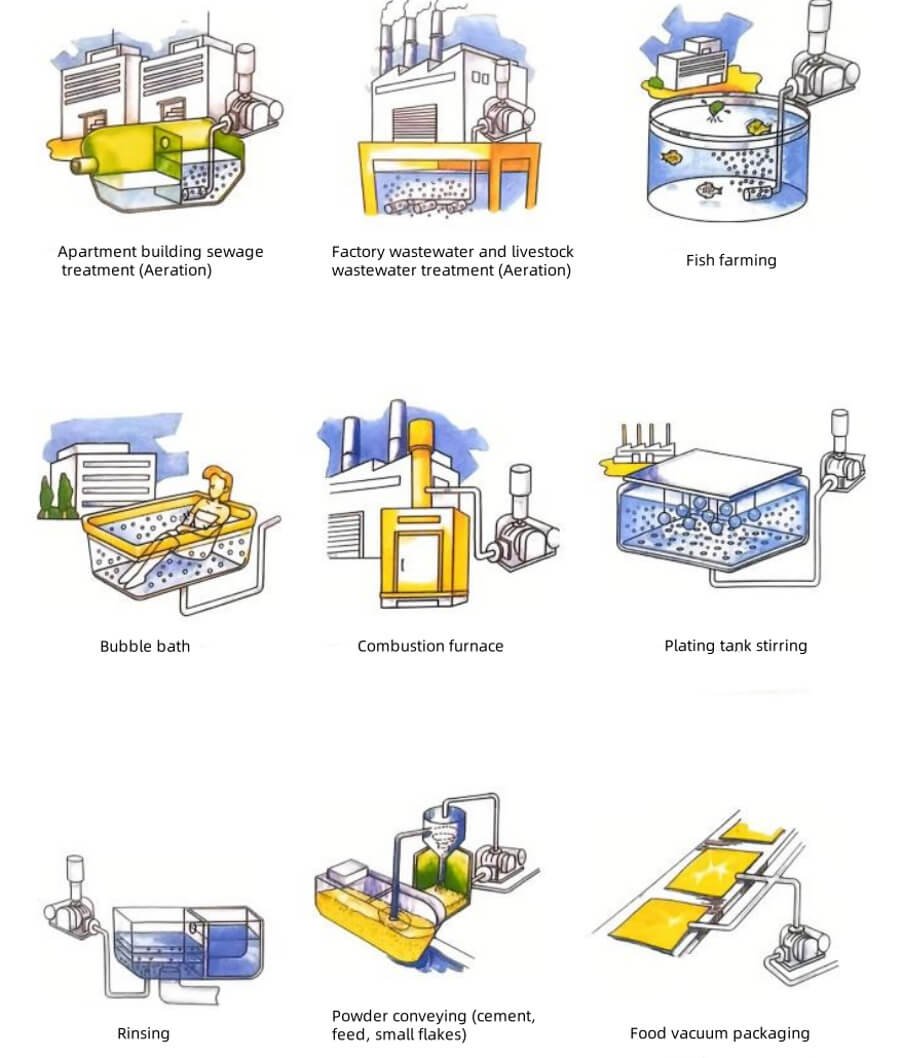

High-pressure Roots blowers are very suitable for the following application scenarios because of their unique performance characteristics: Industrial vacuum: used to collect and treat dust generated during the production process, keep the workshop clean and reduce environmental pollution.Plating tank stirring: Helps evenly mix the chemicals in the plating solution to ensure plating quality.Pneumatic conveying: long-distance transportation of solid particulate materials in industries such as petroleum, chemical industry, smelting, electric power, chemical fertilizers, and building materials.Sewage treatment: As the power source of the aeration system, it supplies oxygen to the bottom of the sewage pool to promote microorganisms to decompose organic matter.Food processing: For example, the gas filling process in the light bulb manufacturing process, or other places where clean, oil-free compressed air is required.Aquaculture: Provide sufficient dissolved oxygen for fish ponds or other aquatic habitats to improve water quality conditions.

City gas: used for pressure regulation and transportation of natural gas pipeline networks to ensure the safety and stability of residents' daily gas use.