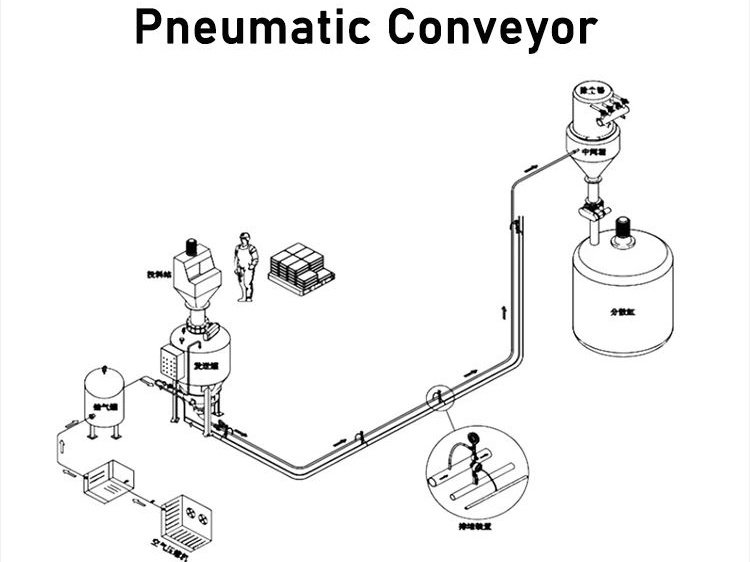

As industries worldwide seek safer and more efficient ways to transport fine powders and dust particles, dust particles pneumatic conveying equipment is gaining traction as a reliable solution for bulk material handling. This advanced technology minimizes dust emissions, reduces waste, and enhances workplace safety, making it ideal for sectors like pharmaceuticals, food processing, chemicals, and cement production.

Why Dust Particles Pneumatic Conveying?

Dust-Free Operation: Closed-loop systems prevent particle leakage, ensuring compliance with environmental and workplace safety regulations.

Energy Efficiency: Optimized airflow and low-pressure systems reduce energy consumption by up to 25%.

Gentle Material Handling: Designed for fragile powders, preventing degradation during transport.

Easy Maintenance: Modular designs simplify cleaning and reduce downtime.

Key Industry Applications

Pharmaceuticals: Hygienic transfer of active ingredients (APIs) and fine powders.

Food & Beverage: Safe handling of flour, spices, and powdered additives.

Chemicals: Dust-free transport of hazardous or reactive materials.

Cement & Mining: Efficient movement of fly ash, silica, and other fine particulates.

Latest Innovations

Smart Monitoring: IoT-enabled sensors track airflow and pressure in real time, preventing blockages.

Explosion-Proof Designs: ATEX-compliant systems for flammable dust environments.

Customizable Solutions: Tailored setups for high-capacity or ultra-fine material handling.

Market Growth

The global pneumatic conveying market is expected to reach $35 billion by 2027, with dust-handling systems leading the charge.

Learn more about how pneumatic conveying solutions can transform your operations at Https://Pneumaconvey.Com/.