Product

Mechanical seal Roots blower

The mechanical seal Roots blower is a three-blade Roots blower with special sealing technology. It uses precision mechanical seals to prevent gas leakage and lubricating oil from entering the working chamber. This design not only improves the working efficiency of the equipment, but also ensures the purity of the output gas, making it suitable for application scenarios that have strict requirements on gas purity. Mechanically sealed Roots blowers are widely used in many industries due to their high efficiency, low noise, and no need for internal lubrication.

Principle

The fan casing is equipped with two sets of three-blade impellers, which are driven by a pair of synchronized gears to reciprocate in opposite directions. The air inlet volume is V1 due to the rotation of the impeller, which forms a low pressure. At the same time, the sucked air volume is V2. The resistance of the air outlet increases to produce high-pressure gas. , thereby sending out air; since there is a certain gap between the impellers and between the impellers and the casing, there is no friction, so it can operate for a long time.

Parameter

| Fan pressure | Medium pressure fan MPa |

| Type | Roots blower |

| Material | cast iron |

| Voltage | 380V |

| Air volume | 60-120m*/h |

| Power | 1.5W |

| Compressive strength | 0.1MPa |

| Frequency | 50Hz |

| Model | GHSR50MF |

| Performance | Special gas delivery |

| Number of leaves | 3 slices |

| Weight | 150kg |

| Speed | 1100-1400r/min |

| Specification | third line |

| Use | Special gas delivery |

| Wind pressure | 10-100kpa |

| Processing and customization | yes |

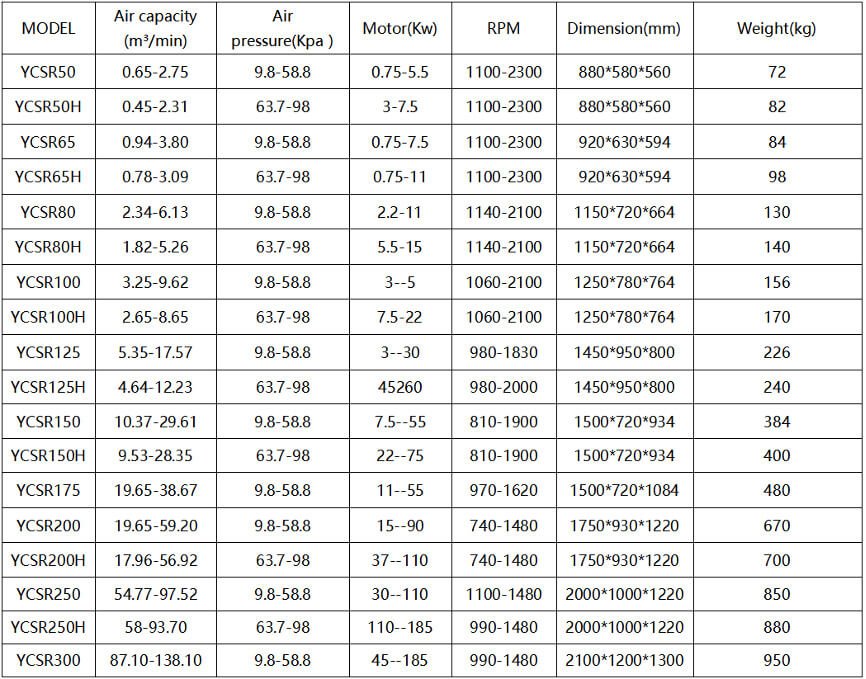

Single fuel tank: YCSR-(50/65/80/100/125/150/175/200/250/300)

High-pressure double fuel tank: YCSR-(80/100/125/150/200/250/300)H

Intensive: YCSR-MJ(50/65/80/100/125/150/175/200/250)

Roots vacuum pump: YCSR-(80/100/125/150/200/250/300)V

Features and Advantages

High efficiency: The mechanical seal Roots blower has high volume utilization and volumetric efficiency, which can reduce energy consumption while ensuring performance.

Low noise: Due to the use of three-blade rotor design and advanced sealing technology, the vibration and noise generated during operation are low.

No internal lubrication required: There are no friction parts inside, so there is no need to use lubricating oil, which reduces maintenance costs and avoids the risk of oil contamination.

Long life: The quality of mechanical seals directly affects the service life of the entire blower. Seals made of high-quality materials can maintain a good sealing state for a long time.Cleaning process: It is very suitable for applications that need to transport clean, oil-free compressed air or other gases, such as food processing, pharmaceutical manufacturing and other fields.

Compact structure: The overall design is compact, easy to install and arrange, while reducing the floor space.

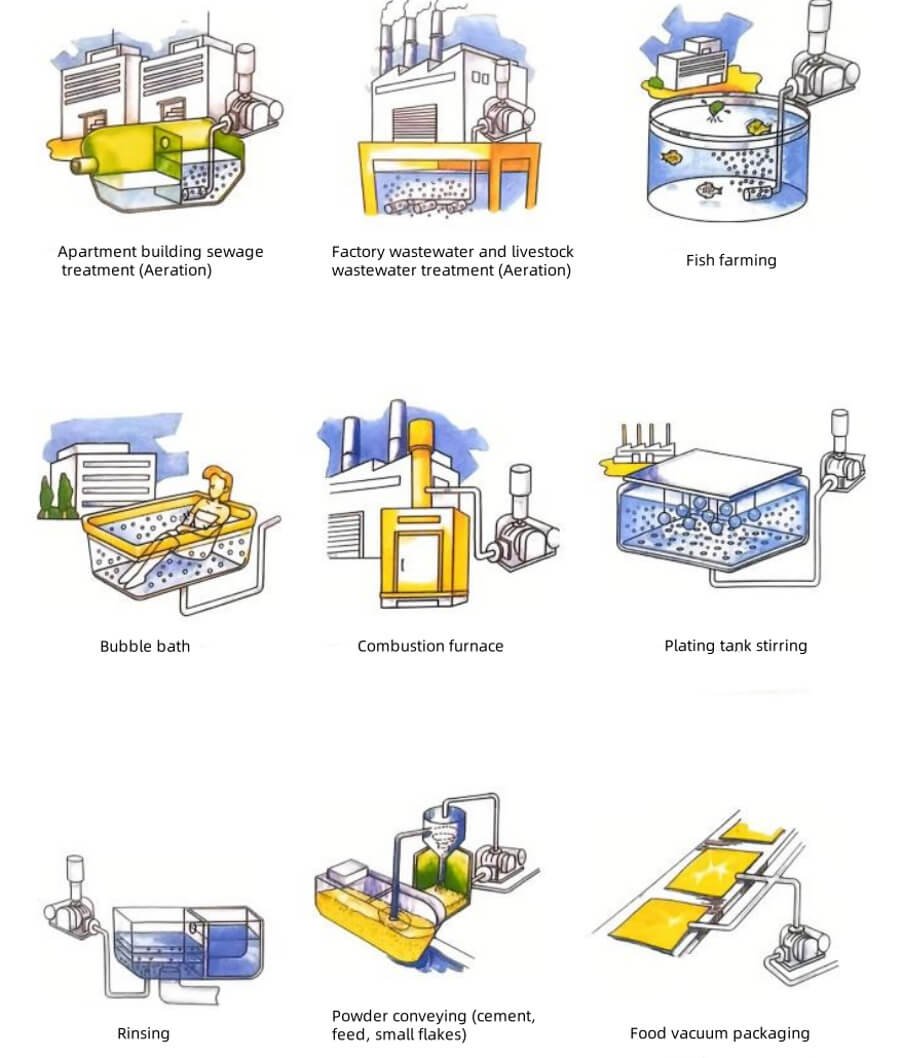

Easy to maintain: Although mechanical seals add complexity, due to their high reliability, actual maintenance requirements are less. Daily maintenance mainly includes checking the status of the seals and replacing worn parts. Usage Scenarios

Mechanical seal Roots blowers are particularly suitable for the following application scenarios due to their unique performance characteristics: Pharmaceutical industry: Used in vacuum drying, crystallization and other processes for drug production to ensure product quality is not contaminated.

Chemical industry: Pressurized transportation of gases required for chemical reactions, such as recovery and reuse of carbon dioxide in the production of ammonia and methanol.

Food and Beverage: Provide carbon dioxide pressurization services in carbonated beverage filling lines to ensure product quality; or serve as vacuuming equipment in the food packaging industry.

Electronic semiconductors: Provide a high-purity gas environment in key links such as wafer manufacturing, packaging and testing to prevent impurities from affecting product quality.Medical health: Hospital operating rooms, laboratories and other places require sterile, oil-free compressed air supply for the operation of ventilators, dental equipment and other medical equipment.

Environmental protection project: The aeration and oxygenation system of the sewage treatment plant ensures that microorganisms in the water have enough dissolved oxygen for biological treatment.

Electric power generation: Auxiliary flue gas desulfurization (FGD) systems in coal-fired power plants to help remove pollutants such as sulfur dioxide.

Mining and metallurgy: used for mine ventilation to ensure safe conditions on underground working surfaces, especially in environments containing flammable and explosive gases.