Product

Pneumatic conveying air source blower

This type of fan serves as the power source of the pneumatic conveying system and is responsible for transporting powdery or granular materials from one place to another through pipelines.

Principle

The pneumatic air source Roots blower uses two three-bladed rotors that do not contact each other but rotate synchronously to form a series of sealed working volumes in the cylinder. As the rotor rotates, these volumes sequentially suck in gas from the air inlet, compress it in the enclosed space, and then discharge it from the exhaust port. In order to meet the needs of pneumatic conveying technology, this type of blower pays special attention to the following aspects: Large flow rate and appropriate pressure: It can provide sufficient gas flow and appropriate pressure boosting capacity according to the conveying distance and material characteristics to ensure that the material moves smoothly along the pipeline.

Wear-resistant design: Considering that a large number of fine particles may be carried during the transportation process, wear-resistant materials are used to manufacture key components, and the internal structure is optimized to reduce the risk of wear.

High efficiency and energy saving: The advanced rotor design improves volumetric efficiency and reduces energy consumption; at the same time, operating parameters can be adjusted according to actual working conditions to achieve optimal energy conversion.

Stability and reliability: Optimized design reduces maintenance requirements and extends service life; the internal structure is sturdy and durable, and can effectively resist the impact of dust and other impurities.

Parameter

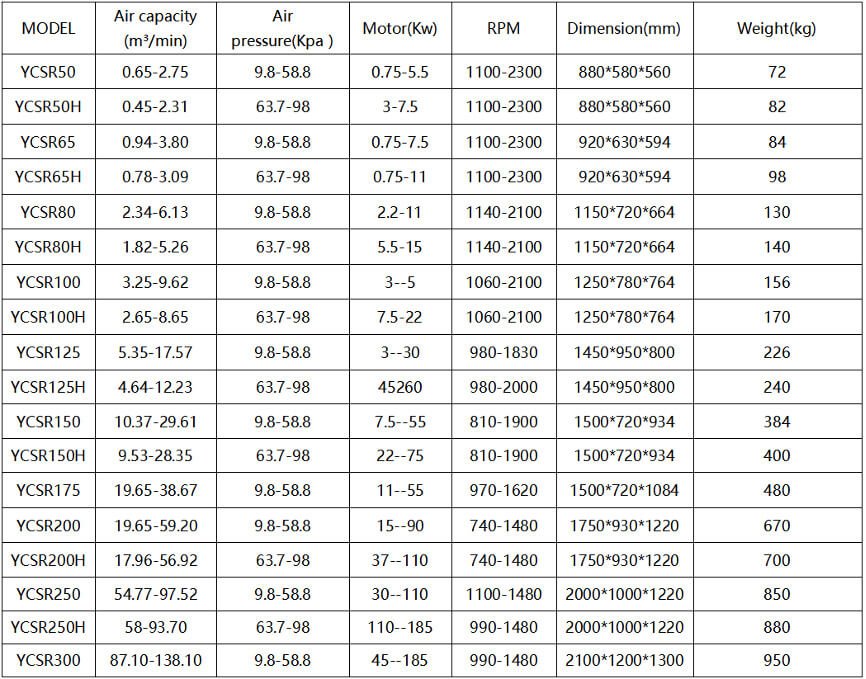

Single fuel tank: YCSR-(50/65/80/100/125/150/175/200/250/300)

High-pressure double fuel tank: YCSR-(80/100/125/150/200/250/300)H

Intensive: YCSR-MJ(50/65/80/100/125/150/175/200/250)

Roots vacuum pump: YCSR-(80/100/125/150/200/250/300)V

Features and Advantages

High conveying efficiency: The pressure and flow rate of the output gas can be adjusted within a wide range to ensure that materials move along the pipeline stably and quickly.

Low noise and vibration: Using a three-blade rotor design and advanced sealing technology, the vibration and noise generated during operation are lower, providing a quieter working environment.

No internal lubrication required: There are no friction parts inside, so there is no need to use lubricating oil, which reduces maintenance costs and avoids the risk of oil contamination.

Long life and low maintenance: High-quality materials and manufacturing processes ensure long-term reliable operation of the equipment. Daily maintenance mainly includes checking the status of seals and replacing worn parts.Compact structure: The overall design is compact, easy to install and arrange, while reducing the floor space.

Strong flexibility: The output parameters can be adjusted according to different material types and conveying requirements to adapt to various pneumatic conveying tasks.

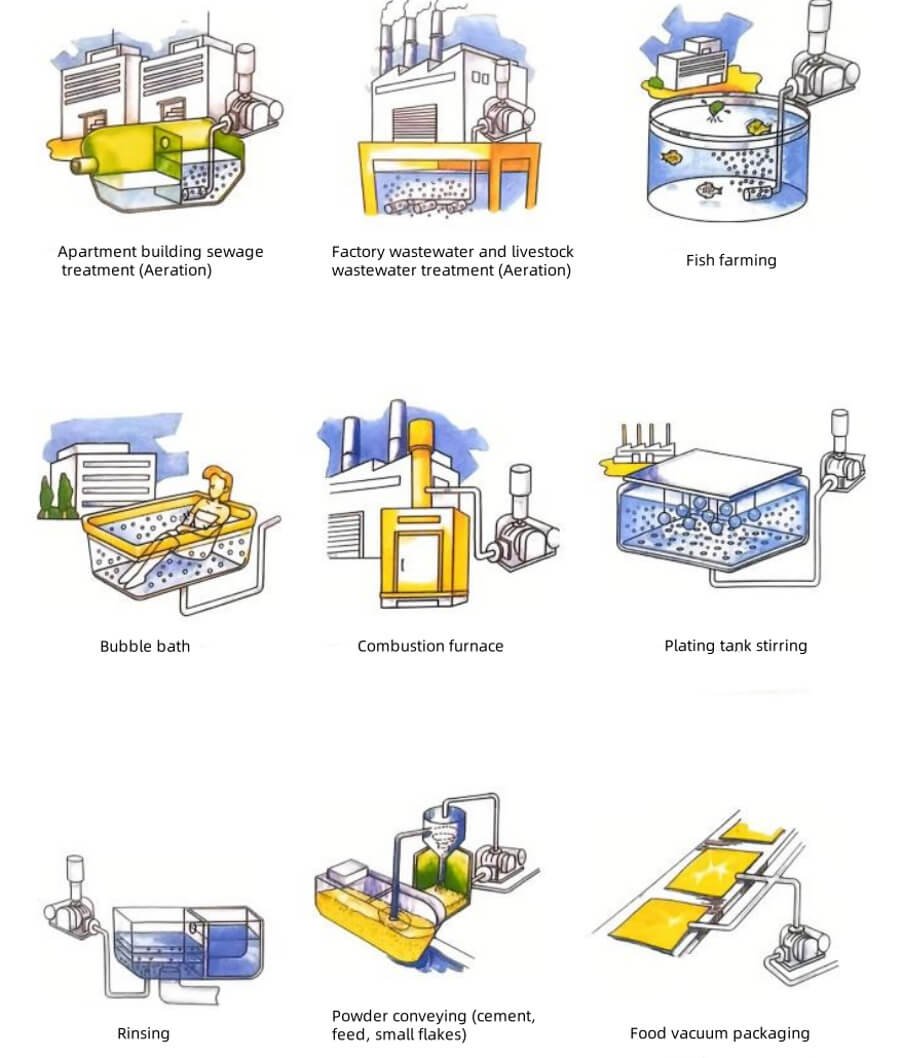

Cleaning process: It is very suitable for applications that need to transport clean, oil-free compressed air or other gases, such as food processing, pharmaceutical manufacturing and other fields. Usage Scenarios

Roots blowers for pneumatic conveying air sources play an important role in many fields because of their unique performance characteristics. They are especially suitable for the following application scenarios: Cement Industry: Used to transport raw materials such as clinker and fly ash from one location to another, such as from a mill to a storage or packaging station.

Grain processing: In flour mills, feed mills and other places, it is used to transport grains, beans and other materials to improve production efficiency and reduce labor input.

Chemical industry: Participate in the pressurized transportation of raw materials required for chemical synthesis, such as the transportation of plastic particles, fertilizers, etc.; especially when handling corrosive or toxic and harmful substances, gas quality must be strictly controlled.

Mining and metallurgy: used to transport fine powder after crushed ore to ensure the smooth progress of the mineral processing process; it can also be used for the collection and transfer of metal powder.Electric power generation: auxiliary fuel delivery system of coal-fired power plants, helping to transport coal from storage areas to boiler rooms; also suitable for fuel handling in biomass power generation projects.

Food and Beverage: Provide carbon dioxide pressurization services in carbonated beverage filling lines to ensure product quality; or serve as vacuum equipment in the food packaging industry to ensure food safety.

Pharmaceutical industry: Used in vacuum drying, crystallization and other processes for drug production to ensure that product quality is not contaminated; especially when chemical reactions or biological products are involved, gas purity must be strictly controlled.