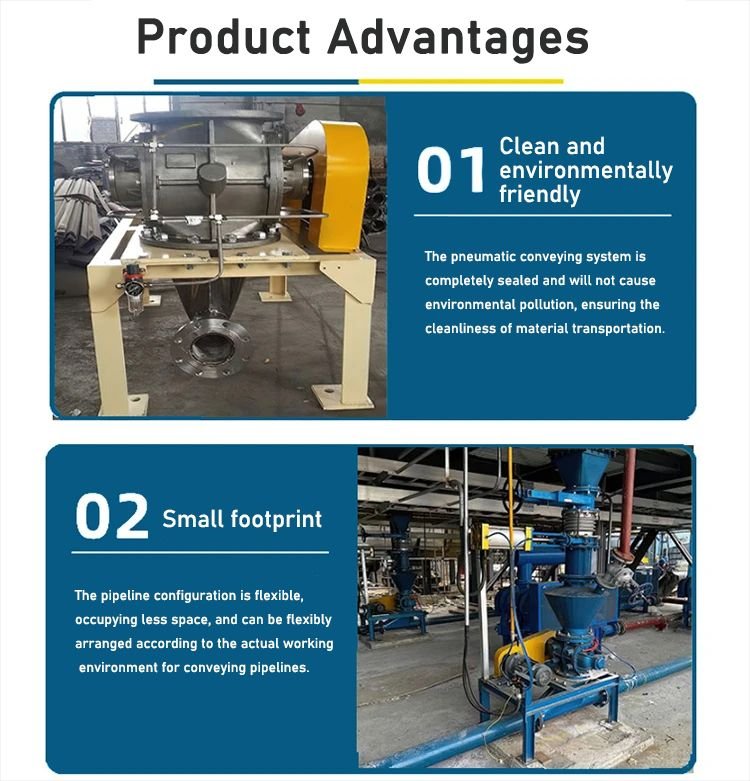

Product

Pneumatic Conveying System For Dry Bulk Materials

Ideal for food, pharmaceuticals, chemicals, cement, and more, our system ensures hygienic, safe, and efficient transport of powders, granules, and pellets. Customizable, energy-efficient, and low-maintenance, it’s perfect for industries requiring contamination-free and reliable material handling. Upgrade your operations today!

Product Description

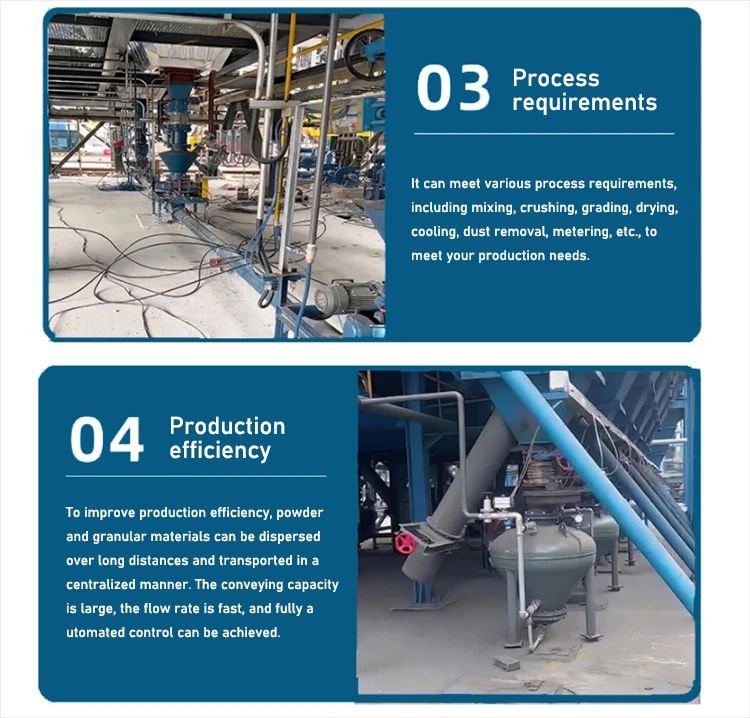

The working principle of pneumatic conveying system mainly involves the interaction between airflow and materials.

Specifically, the pneumatic conveying system transports materials from the starting point to the endpoint through high-pressure air or compressed air, which can be horizontal, vertical, or inclined. During the transportation process, the material is driven by the airflow and suspended in the pipeline, or forms a group to move along the pipeline. Pneumatic conveying systems can be divided into positive pressure conveying and negative pressure conveying, as well as dilute phase conveying and dense phase conveying. Positive pressure conveying uses high-pressure air to push the material, while negative pressure conveying uses vacuum suction to suck the material into the collection point. Dilute phase conveying is usually used for situations where the conveying distance is short and the material content is low, while dense phase conveying is suitable for long-distance and high concentration material conveying.

In addition, pneumatic conveying systems can also perform physical operations such as heating, cooling, drying, and airflow classification of materials simultaneously during the conveying process, or perform certain chemical operations.

The points availatle working-fault variety aggregates of perfomance each material conveying equipment for perfomance and efficiency has very big effect. Thereore in the selexted device before/the performance measurement. Suitable for conveying material as common:

| Flour | Bean cake | Season powder | Fishmeal | Wheat | Coca | Salt | Com | Soybean | Potato powder | hull |

| Dry leavening | Cottonseed | Fibrin | Amylum | Granule | Fodder | Tobacco leaf | French chalk | Dolomite | Powdered glucose | Monosodum glutamake |

| Limestone | Magnesia | Aluminum dioxide | Titanium whiteing | kaolin | Fluoresce powder | Boric moist soil | clay | Laterite | Lmenite powder | Rice hull |

| White dust | Fedspar | Scour pwder | Fertilize | Glauber’s | Carbamide | Zinc oxide | Calcium hydroxide | Sodium carbonate | Cement | Gaphite |

| silica gel | Sodium nitrate | Hydroxid aluminum | Chlorate | Phosphate | Phosphatic | Borax | Land plaster | Zinc powder | Mine Powder | Silicon aluminum ball |

| Nickel powder | Carbon blace | Ferrice | HDPE | PTA | PET | ABS | SBS | PVA | PVC | EPS |

| Coal powder | Flyash | Nylon slices | Carbon element | Coke pranule | Cement | Lron pellet | Rubber granule | Sawdust | Biology enzyme | PPS |

| Accelerant | Heavy calcium | Land plaster | Fiberglass | Lusine | Bran | Found day | Dry salt | Protein | MOCA | CPE |

| Germ | Fruit dreg | Soybean | Gelatin | Corundum | Z silica gel | Lime powder | White stone powder | BHT | Soap grain | Cobalt powder |

| Sour cream | Cotncob powder | Thin film | Com fibers | PVC modifier | Alkaline cellulose | Magnesium | Alumina | Lxalic acid cobalt powder | Aluminum particles | PS |

| PP | Petrolem coke | Slag powder | PE | Electrially calcined coal | Smelter Coke |

Application

Our Pneumatic Conveying Systems are widely used across industries for efficient and hygienic material handling:

- Food & Beverage: Transport flour, sugar, spices, and grains.

- Pharmaceuticals: Handle powders, APIs, and granules safely.

- Chemicals: Convey polymers, resins, and catalysts.

- Cement & Construction: Move cement and fly ash effortlessly.

- Plastics: Transfer pellets and recycled materials.

- Agriculture: Transport grains, seeds, and animal feed.

- Mining: Handle ores, minerals, and abrasive materials.

- Energy: Manage fly ash, biomass, and fuel materials.