Product

Pneumatic Oscillating Valve

Pneumatic Oscillating Valve also known as pneumatic flap valve or pneumatic butterfly valve, is a valve device that uses compressed air to drive an actuator to control the rotation of the valve blades to start, stop or adjust the material flow. It is widely used in pneumatic conveying systems to accurately control the flow of gas or dry bulk materials (such as powders, granules, etc.). Pneumatic swing valves play an important role in ensuring the stable operation of the system with their fast response, high sealing and reliability.

Principle

When the air source is introduced from the upper air inlet, the valve stem drives the valve plate to move downward and the valve closes. When the air source is introduced from the lower air inlet, the cylinder drives The valve plate swings left and right, and the valve opens.A spring is loaded between the valve plate and the valve seat. The elastic force of the spring always presses the valve plate against the valve seat to ensure the sealing of the valve and allows the valve plate to move vertically up and down. Directional movement, which helps to compensate for the thermal expansion and contraction of valve parts, and can overcome the impact of any back pressure changes on the seal and prevent particulate media from entering between the two sealing surfaces.During the opening and closing process, the valve plate can rotate, causing grinding and polishing effects between the sealing surfaces. Moreover, because the valve body is eccentric to the channel, when the material is opened and discharged, a vortex will be generated, and the material vortex formed will clean the valve on its own. lumen. All these features make this valve have a long service life, providing a reliable guarantee for the safe operation of your system. Applicable media: fly ash, dry dust, gas, water, etc.

Scope of application: Dry ash system of thermal power plant, warehouse pump discharging and transportation. Bulk material conveying systems in chemical, metallurgical, papermaking, pharmaceutical and other industries

system. Various abrasive media are used for opening and closing on pipelines. Parameter

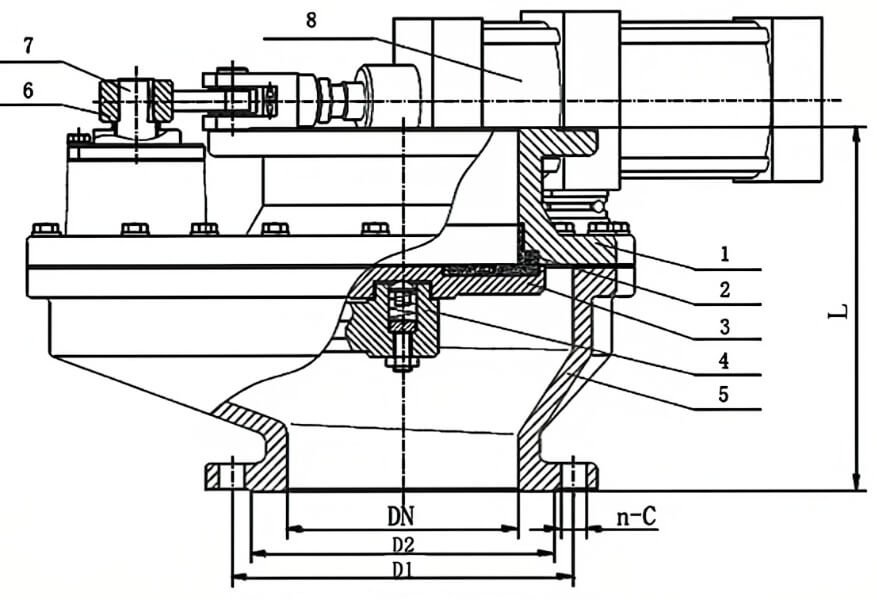

(PN1.0mpa valve dimensions parameters)

| Specification | Flange link distance | Seal diameter | The latest hole distance of flange connection | Number of flange holes | Flange link diameter | Weight | |

| Name | DN | L | D2 | D1 | n | C | kg |

| DN150 | 330 | 263 | 240 | 8 | 22 | 95 | |

| DN200 | 310 | 320 | 295 | 8 | 22 | 110 | |

| Swing valve | DN250 | 340 | 375 | 350 | 12 | 22 | 170 |

| DN300 | 425 | 375 | 400 | 12 | 22 | 230 |

| Serial number | Name | Material |

| 1 | Upper seat | Ductile Iron |

| 2 | Sealing ring | Ceramic or alloy |

| 3 | Valve plate | Ceramic or alloy |

| 4 | Swing arm | Ductile Iron |

| 5 | Lower valve body | Ductile Iron |

| 6 | Rocker arm | Ductile Iron |

| 7 | Shaft | 45# steel |

| 8 | Pneumatic actuator | Aluminum cylinder |

Features and Advantages

Quick response: Due to the use of pneumatic actuators, the pneumatic swing valve can complete the switching action in a short time and respond quickly.

High sealing: The special sealing design ensures zero leakage in the closed state, ensuring the air tightness and material integrity of the system.

Wear-resistant and durable: Made of high-quality materials to extend service life and reduce maintenance costs.

Large flow area: Compared with other types of valves, the pneumatic swing valve has a larger flow area, which reduces fluid resistance and improves transportation efficiency.

Strong adaptability: It can handle various types of materials and is not affected by the humidity and viscosity of the materials. It is especially suitable for fragile or sensitive materials.

Safe and reliable: Equipped with multiple protection mechanisms, such as overload protection, short circuit protection, etc., to ensure the safety of personnel and equipment.

Easy to install and maintain: The compact design makes it easy to integrate into existing pipelines and facilitate maintenance. Usage Scenarios

Pneumatic swing valves are widely used in all aspects of pneumatic conveying systems, especially where precise material management and control are required.- Chemical industry

- Oil industry

- Water treatment industry

- Construction industry

- Machinery industry

- Metallurgical industry