Product

Roots blower bearings

Roots blower bearings are key components that support the rotation of the rotor (impeller) and reduce friction. They not only ensure the smooth operation of the equipment, but also directly affect the efficiency, reliability and service life of the Roots blower. Selecting the appropriate bearing type and material, as well as implementing the correct maintenance strategy, are critical to maintaining optimal performance from your Roots blower.

Principle

The main function of Roots blower bearings is to support the rotor and improve transmission efficiency by minimizing friction losses. The specific working process is as follows: Supporting function: Bearings are installed at both ends of the rotor to withstand the radial force and axial force from the rotor to ensure that the rotor can rotate stably.

Reduce friction: The lubricant (oil or grease) forms a protective film and establishes a hydrodynamic effect between moving parts, thereby significantly reducing frictional resistance.

Heat dissipation and cooling: Some bearing designs allow the lubricating oil to take away the heat generated by friction, helping to maintain the bearing temperature within a safe range. Parameters: Applicable to the following products

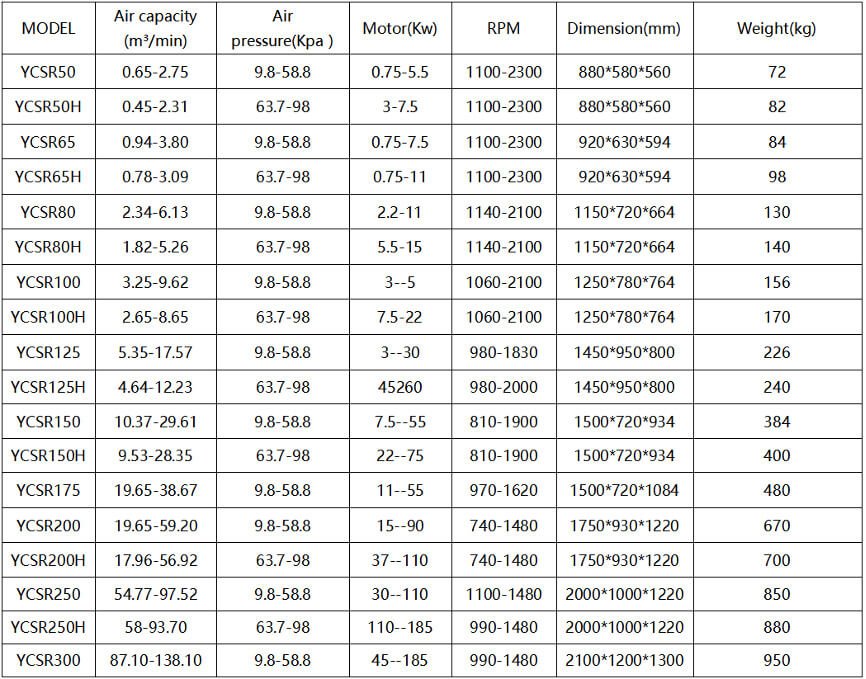

Single fuel tank: YCSR-(50/65/80/100/125/150/175/200/250/300)

High-pressure double fuel tank: YCSR-(80/100/125/150/200/250/300)H

Intensive: YCSR-MJ(50/65/80/100/125/150/175/200/250)

Roots vacuum pump: YCSR-(80/100/125/150/200/250/300)V

Features and Advantages

Efficient vibration reduction: High-quality bearings can effectively absorb and disperse vibration energy, reduce the impact on other components, and extend the life of the equipment.

Low friction loss: Through advanced design and material selection, bearings can significantly reduce friction loss and improve transmission efficiency.

Long life and durability: high-quality materials are selected and rigorously tested, making the bearings have high strength and durability, reducing the frequency of replacement.

Easy to install and maintain: Most bearings are designed with a modular structure for easy on-site assembly and regular inspection and maintenance.Strong adaptability: According to the requirements of different application scenarios, different types of bearings can be selected to meet specific process needs.

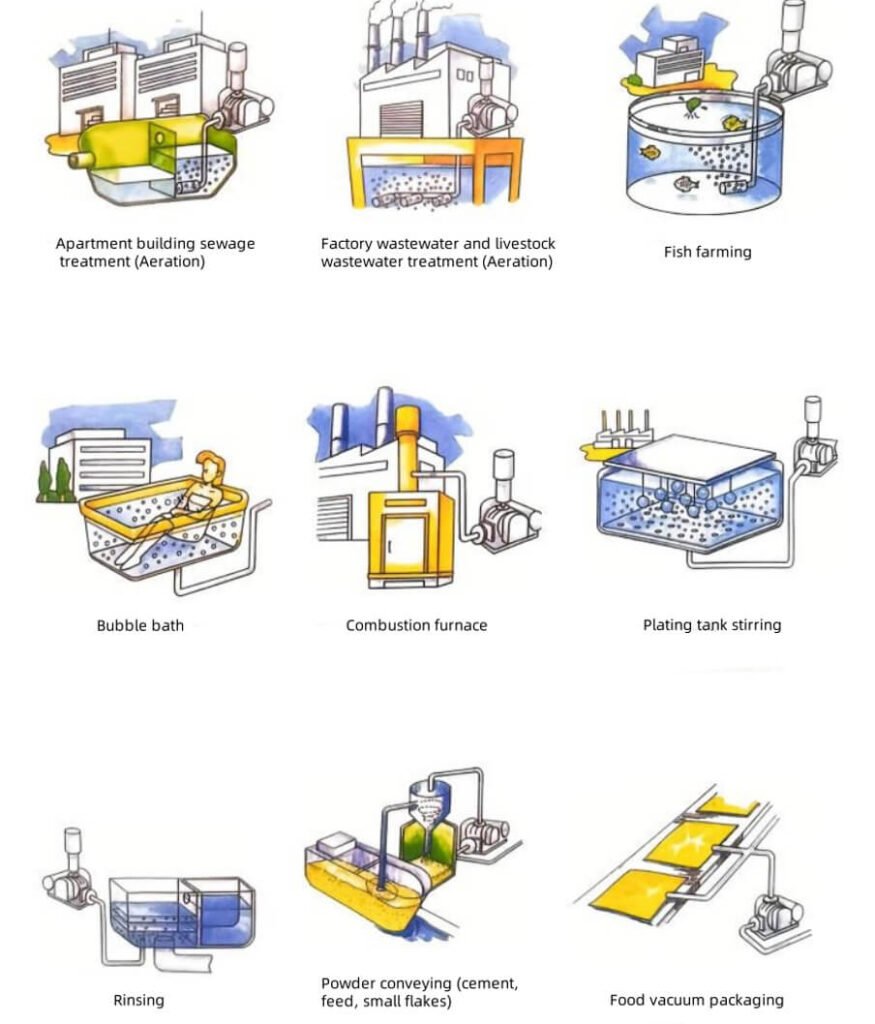

Comply with standards: Many bearing products are manufactured in compliance with international or national standards, such as ISO, ANSI, etc., to ensure that their performance and technical indicators meet industry requirements. Usage Scenarios

Roots blower bearings are widely used in many industries due to their important support and friction reduction functions, and are especially suitable for the following application scenarios: Industrial manufacturing: such as steel plants, cement plants, chemical plants, etc. In these places, Roots blowers are usually used for gas transportation, waste gas treatment and other tasks, and their internal bearings need to withstand harsh working conditions such as high temperature and high pressure.

Sewage treatment: In sewage treatment plants, Roots blowers are used to increase oxygen in the aeration tank, and the bearings need to have good corrosion resistance and stable lubrication properties.

Food processing: Roots blowers used in the food industry require oil-free compression and low-noise operation, but for non-contact parts, bearings still provide the necessary support and friction reduction functions. In special cases, it may be necessary to use food-grade lubricants.Aquaculture: Roots blowers used in aeration systems if they are close to residential areas require bearings to ensure stable operation of the system and ensure the safety of operators.Electricity production: In thermal power plants, Roots blowers are used for boiler ventilation, and bearings ensure that even in emergencies there will be no failure due to poor lubrication.

Mining and Metallurgy: Participated in mine ventilation, smelting furnace gas supply and other tasks, bearings help maintain the pressure balance of the system and prevent safety hazards caused by lubrication problems.