Product

Roots blower check valve

Roots blower check valve (also called check valve or check valve) is a key device used to prevent gas backflow and is installed at the air inlet or exhaust port of Roots blower. It ensures that gas can only flow in the intended direction, thereby protecting equipment from damage caused by reverse airflow and maintaining stable operation of the system. One-way valves play an important role in a variety of application scenarios, especially when it is necessary to maintain pressure balance and prevent media backflow.

Principle

Roots blower check valve works based on simple mechanical principles:Forward flow: When gas flows from the inlet to the outlet, the pressure acting on the valve disc overcomes the resistance of the spring, causing the valve disc to open, allowing the gas to pass smoothly.

Reverse flow: Once gas attempts to flow from the outlet to the inlet, the valve disc will immediately receive pressure from the other side, forcing it to fit tightly against the valve seat to prevent reverse flow of gas.

Automatic reset: When the forward pressure is restored, the spring pushes the valve disc back to the open position and returns to normal working condition. Parameter

Features and Advantages

Efficient anti-backflow: Rapidly responds to changes in gas flow direction, effectively prevents gas backflow, and protects the safety of systems and equipment.

Reliable sealing: High-quality seals and precise design ensure the tightness of the one-way valve in the closed state and prevent gas leakage.

Long life and durability: High-quality materials have been rigorously tested, giving the one-way valve high strength and durability, reducing the frequency of replacement. Usage Scenarios

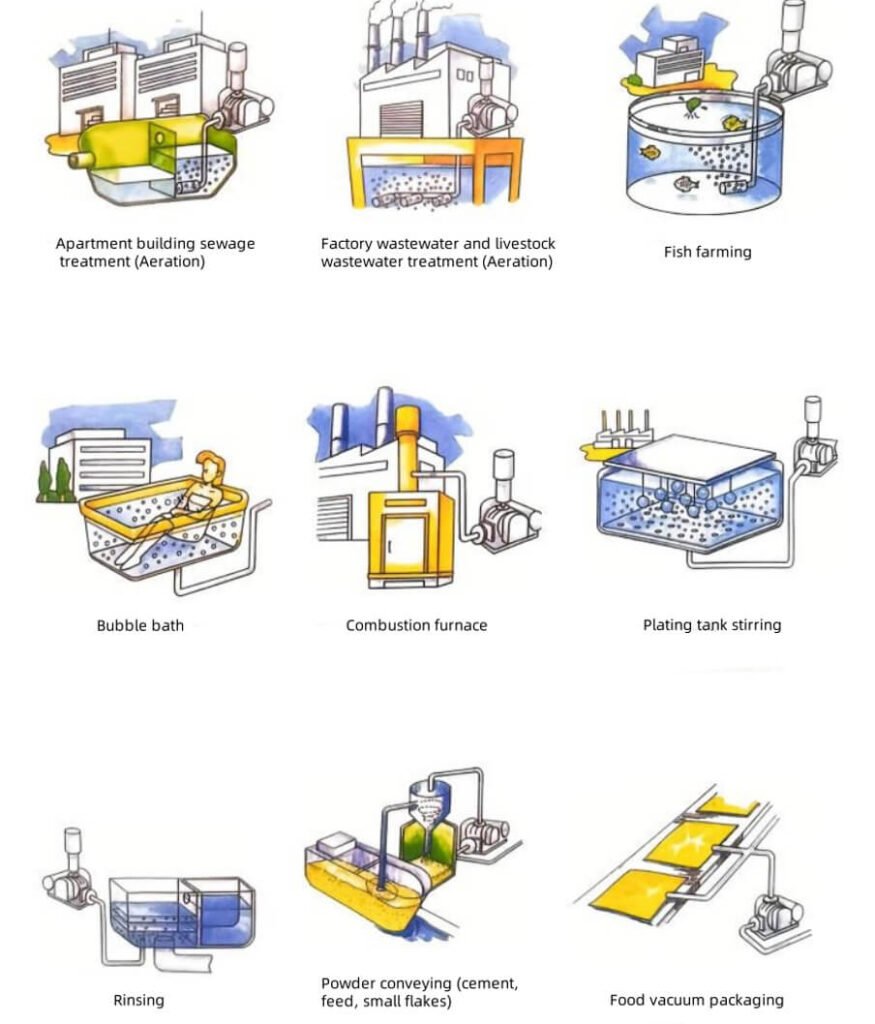

Roots blower check valves are widely used in many industries because of their important protective functions. They are especially suitable for the following application scenarios:Industrial manufacturing: such as steel plants, cement plants, chemical plants, etc. In these places, Roots blowers are usually used for gas transportation, waste gas treatment and other tasks. The one-way valve can prevent gas backflow caused by sudden power outages or other reasons, protecting Equipment is protected from damage.

Sewage treatment: In sewage treatment plants, Roots blowers are used to increase oxygen in the aeration tank, and the one-way valve ensures that gas backflow does not occur even during shutdown, maintaining the normal operation of the system.

Food Processing: Roots blowers used in the food industry require oil-free compression and low-noise operation, and check valves can provide the necessary protection without sacrificing hygiene standards.Aquaculture: If a Roots blower used in an aeration system is located close to a residential area, a one-way valve is required to ensure stable operation of the system and ensure the safety of the operator.

Electric power production: In thermal power plants, Roots blowers are used for boiler ventilation, and one-way valves ensure that gas backflow will not occur even in emergencies, improving the safety of the system.

Mining and metallurgy: Participated in mine ventilation, smelting furnace gas supply and other tasks. One-way valves help maintain the pressure balance of the system and prevent safety hazards caused by gas backflow.