Product

Roots blower elastic joint

The Roots blower elastic joint (also known as a flexible joint or soft connection) is a key component installed between the Roots blower air inlet and exhaust port and the duct system. It is mainly used to absorb vibration, compensate for displacement, reduce noise transmission, and ensure the sealing and stability of the system. By using elastic joints, the service life of the equipment can be effectively extended, maintenance costs can be reduced, and the operating efficiency of the entire gas delivery system can be improved.

Principle

The main functions of Roots blower elastic joints are as follows: Vibration isolation: Since the Roots blower will produce certain mechanical vibrations during operation, if these vibrations are directly transmitted to the pipeline system, they may cause damage to the pipeline or generate additional noise. Elastic joints can absorb this part of vibration energy through their own elasticity and flexibility, thereby protecting pipes and other connecting equipment.

Displacement compensation: Under the influence of factors such as thermal expansion and contraction, foundation settlement, etc., the pipeline system may undergo slight position changes. The elastic joint can freely expand and contract within a certain range to compensate for this displacement and ensure the normal operation of the system.

Sealing guarantee: High-quality elastic joints can maintain a tight sealing effect while maintaining good flexibility, prevent gas leakage, and ensure the safety and reliability of the system.Noise Attenuation: Elastomeric joints also act as acoustic barriers, helping to reduce noise transmitted from the blower to the ductwork, improving the quality of the work environment. Parameter

| Nominal diameter DN | Length L | Number of screws | Bolt hole | Bolt hole center | Axial displacement mm | Lateral displacement | deflection angle | ||

| mm | n | D | D | mm | 4 | ||||

| mm | inch | 直径 mm | 圆直径mm | elongation | compression | ||||

| 32 | 7/17 | 95 | 4 | 18 | 100 | 6 | 9 | 9 | 15 |

| 40 | 17 | 96 | 4 | 18 | 110 | 6 | 10 | 10 | 15 |

| 50 | 2 | 105 | 4 | 18 | 125 | 7 | 10 | 10 | 15 |

| 66 | 29 | 115 | 4 | 18 | 145 | 7 | 13 | 11 | 15 |

| 80 | 3 | 135 | A | 18 | 160 | 8 | 15 | 12 | 15 |

| 100 | 4 | 150 | 8 | 18 | 180 | 10 | 19 | 13 | 15 |

| 125 | 5 | 165 | 8 | 18 | 210 | 12 | 19 | 13 | 15 |

| 150 | 6 | 180 | 8 | 23 | 240 | 12 | 20 | 14 | 16 |

| 200 | 8 | 210 | 8 | 23 | 295 | 16 | 25 | 22 | 15 |

| 250 | 10 | 230 | 12 | 23 | 350 | 16 | 25 | 22 | 16 |

| 300 | 12 | 245 | 12 | 23 | 400 | 16 | 25 | 22 | 15 |

| 350 | 14 | 255 | 16 | 23 | 460 | 16 | 25 | 22 | 15 |

| 400 | 16 | 255 | 16 | 25 | 515 | 16 | 25 | 22 | 15 |

| 450 | 18 | 255 | 20 | 25 | 665 | 16 | 25 | 22 | 15 |

| 500 | 20 | 255 | 20 | 25 | 620 | 16 | 25 | 22 | 15 |

| 550 | 22 | 260 | 20 | 30 | 675 | 16 | 25 | 22 | 15 |

| 600 | 24 | 260 | 20 | 30 | 725 | 16 | 25 | 22 | 16 |

| 650 | 26 | 260 | 24 | 30 | 780 | 16 | 25 | 22 | 15 |

| 700 | 28 | 260 | 24 | 30 | 840 | 16 | 25 | 22 | 15 |

| 800 | 32 | 260 | 24 | 34 | 950 | 16 | 25 | 22 | 16 |

| 900 | 36 | 260 | 28 | 34 | 1050 | 16 | 25 | 22 | 15 |

| 1000 | 40 | 260 | 28 | 34 | 1160 | 18 | 26 | 24 | 15 |

| 1100 | 44 | 260 | 32 | 36 | 1270 | 18 | 26 | 24 | 15 |

| 1200 | 48 | 260 | 32 | 41 | 1380 | 18 | 26 | 24 | 15 |

| 1400 | 56 | 350 | 36 | 34 | 1540 | 20 | 28 | 26 | 15 |

| 1500 | 60 | 300 | 36 | 42 | 1630 | 25 | 35 | 30 | 10 |

| 1600 | 64 | 350 | 36 | 34 | 1760 | 25 | 35 | 30 | 10 |

| 1800 | 72 | 350 | 44 | 41 | 1970 | 25 | 35 | 30 | 10 |

| 2000 | 80 | 420 | 48 | 48 | 2180 | 25 | 35 | 30 | 10 |

| 2200 | 88 | 420 | 52 | 48 | 2390 | 25 | 35 | 30 | 10 |

| 2400 | 96 | 450 | 56 | 48 | 2600 | 25 | 35 | 30 | 10 |

| 2600 | 104 | 500 | 60 | 54 | 2810 | 25 | 35 | 30 | 10 |

| 2800 | 112 | 550 | 64 | 54 | 3020 | 25 | 35 | 30 | 10 |

Features and Advantages

Efficient vibration reduction: Through its unique structural design and material properties, it can significantly reduce the impact of vibrations generated by mechanical equipment on the piping system.

Reliable sealing: Even under frequent expansion and contraction, it can maintain a good sealing effect and prevent gas leakage.

Long life and durability: The use of high-quality materials and rigorous testing make the elastic joints have high strength and durability, reducing the frequency of replacement.

Easy to install and maintain: Most elastic joints are designed with a modular structure for easy on-site assembly and regular inspection and maintenance.

Strong adaptability: According to the requirements of different application scenarios, different types of elastic joints can be selected to meet specific process needs.

Environmentally friendly: By reducing unnecessary noise emissions, it helps companies comply with environmental regulations and enhance their social responsibility image. Usage Scenarios

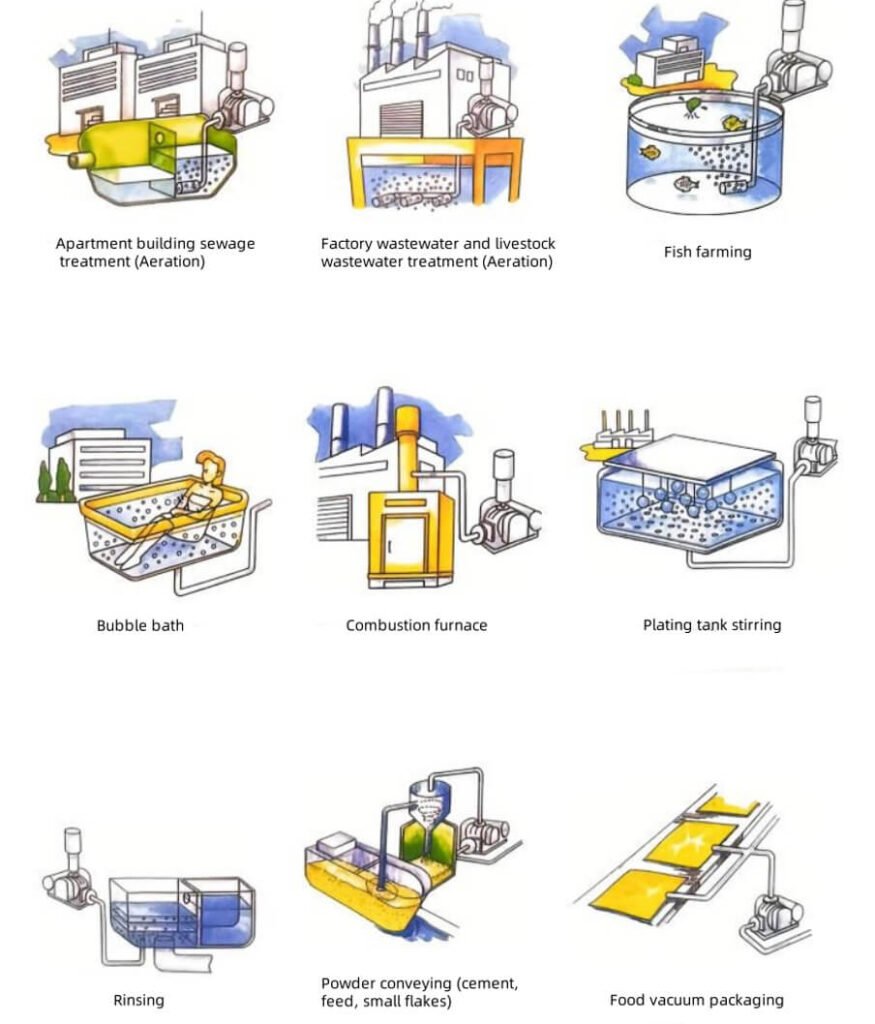

Widely used in gas transportation and pressurization in sewage treatment (such as aeration), chemical industry, food processing, pharmaceutical and other industries.