Product

roots blower gear

The Roots blower gear is one of the key components of the internal transmission system of the Roots blower. It is responsible for transmitting the rotational motion of the motor to two or more three-bladed rotors (also called impellers) to achieve the suction, compression and discharge of gas. . These gears not only need to have high strength and wear resistance, but also must ensure precise synchronous rotation to avoid contact between the rotors to ensure safe and stable operation of the equipment.

Principle

The main function of the Roots blower gear is to transmit power through the meshing between the gears, so that the two rotors can keep rotating in opposite directions synchronously. The specific working process is as follows: Power input: The motor transmits rotational power to the driving gear through the coupling.

Power transmission: The driving gear meshes with the driven gear to transmit power to the other rotor.

Synchronous rotation: Since the gear ratio is usually 1:1, the two rotors will rotate at the same speed but in opposite directions, ensuring that there will be no collision between them.

Gas transportation: As the rotor rotates, a series of sealed working volumes are formed in the cylinder. Gas is sucked in from the air inlet, compressed in the closed space, and then discharged from the exhaust port. Parameter

| Name | blower silencer |

| Classification | Large/Medium/Small |

| Features | Suppress wind noise |

| Color | blue |

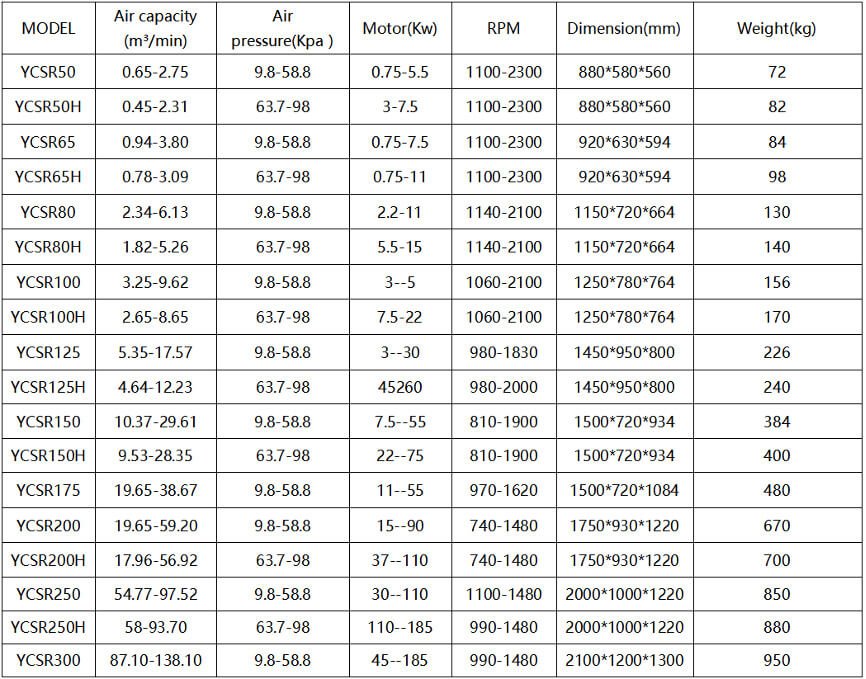

Single fuel tank: YCSR-(50/65/80/100/125/150/175/200/250/300)

High-pressure double fuel tank: YCSR-(80/100/125/150/200/250/300)H

Intensive: YCSR-MJ(50/65/80/100/125/150/175/200/250)

Roots vacuum pump: YCSR-(80/100/125/150/200/250/300)V

Features and Advantages

Efficient transmission: Through precision design and manufacturing, gears can achieve efficient power transmission and reduce energy loss.

Low-noise operation: High-quality gear design and material selection can significantly reduce operating noise and provide a quieter working environment.

Long service life and durability: The use of high-quality materials and strict heat treatment make the gears have high strength and wear resistance, extending the service life.

Easy maintenance: Good lubrication conditions and sealing measures reduce the need for routine maintenance and reduce operating costs.

Reliable synchronization: Precise gear coordination ensures synchronous rotation of the rotors, avoiding the risk of failure caused by out-of-synchronization.Usage Scenarios

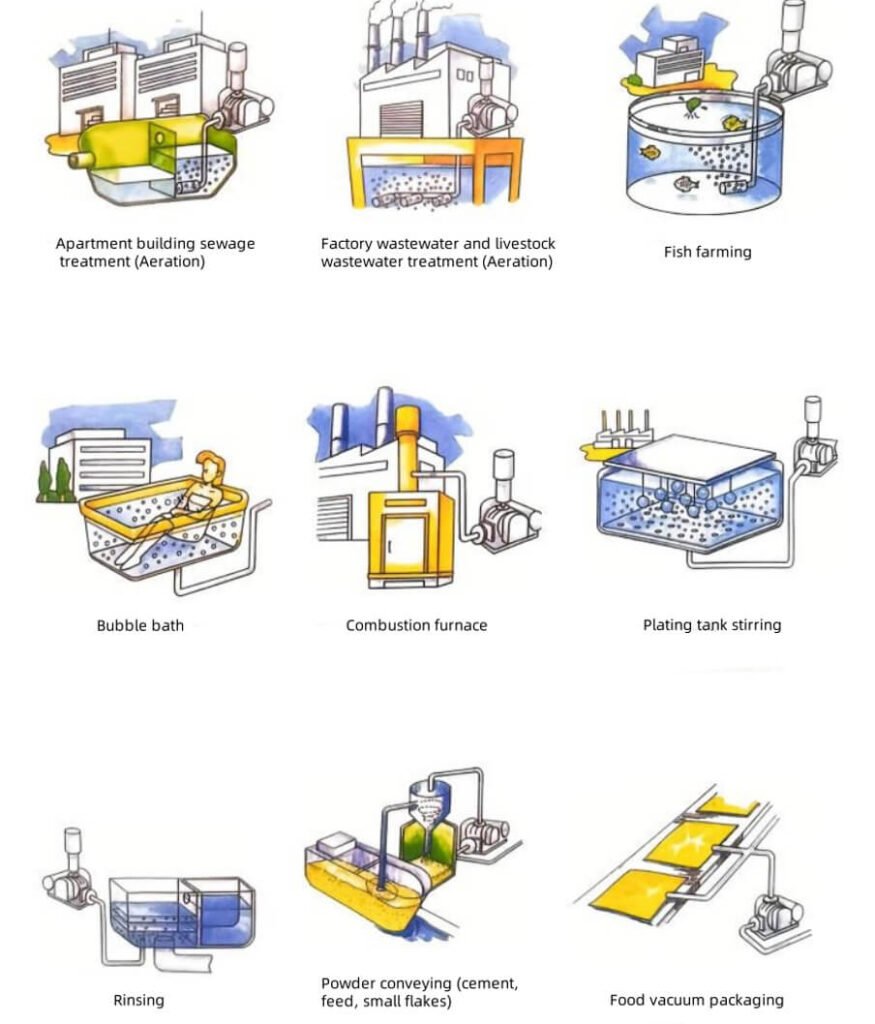

Widely used in gas transportation and pressurization in sewage treatment (such as aeration), chemical industry, food processing, pharmaceutical and other industries.