Product

Roots blower oil standard

Roots blower oil gauge (also called oil level gauge or oil sight glass) is a key component used to monitor the lubricating oil level of Roots blower. It helps operators visually understand the filling status of lubricating oil and ensures that equipment is operating under proper lubrication conditions, thereby extending service life and improving reliability. The design and installation position of the oil indicator are crucial for timely detection of insufficient or excessive lubricating oil.

Principle

The blower oil indicator allows operators to directly see the lubricant level through its transparent viewing window. Oil standards are generally marked with maximum (MAX) and minimum (MIN) scales to indicate the safe lubricating oil range. When the lubricating oil level is lower than the lowest mark, it means that the lubricant needs to be replenished; while if it is higher than the highest mark, it may mean that too much lubricant has been added and there is a risk of overflow.Parameter

| Name | Aluminum alloy oil mirror |

| Washer | Nitrile rubber |

| Material | Aluminum alloy + fiberglass |

| Mirror | polycarbonate |

| Applicable | roots blower |

Features and Advantages

Intuitive and easy to read: The lubricating oil level can be clearly seen through the transparent viewing window for quick inspection.

Strong durability: Made of high-quality materials and rigorously tested, the oil mark has high strength and durability, reducing the frequency of replacement.

Good sealing: High-quality seals ensure the sealing effect of the oil mark and prevent lubricating oil from leaking. Usage Scenarios

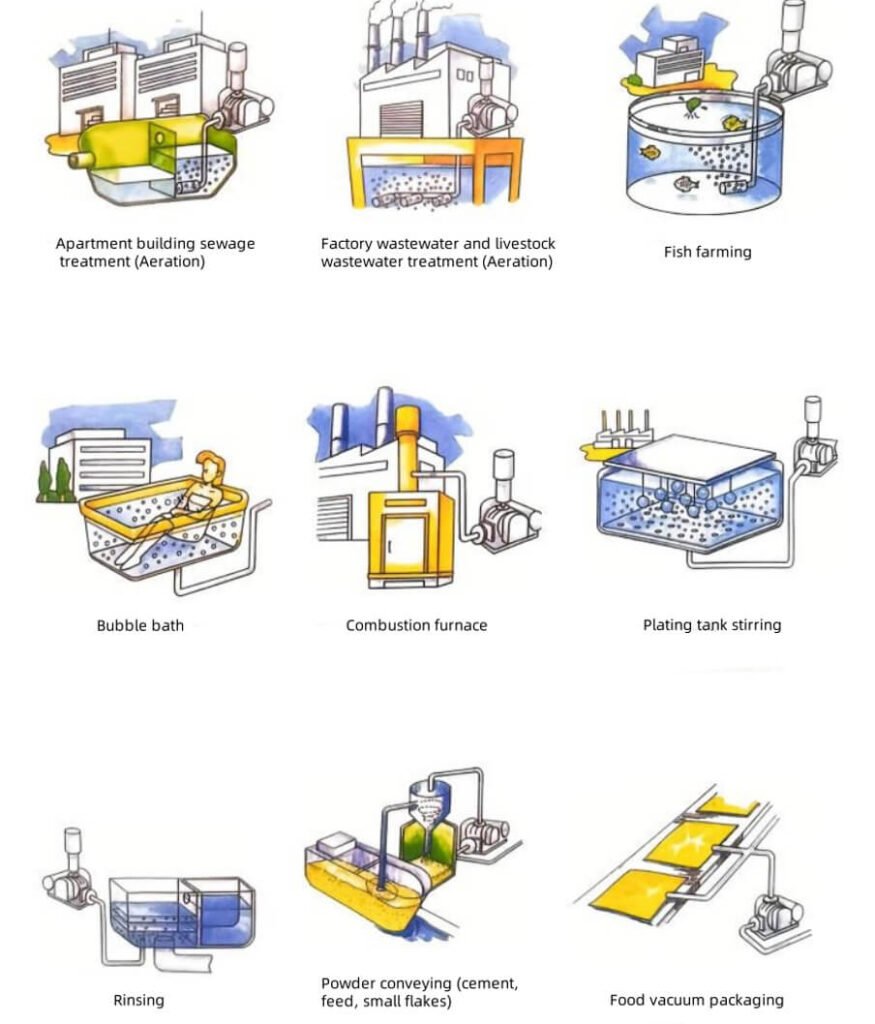

Blower oil gauges are widely used in many industries because of their important monitoring functions, and are especially suitable for the following application scenarios:Industrial manufacturing: such as steel plants, cement plants, chemical plants, etc. In these places, Roots blowers are usually used for gas transportation, waste gas treatment and other tasks. The oil mark can help operators detect lubricating oil problems in time and avoid problems caused by poor lubrication. fault.

Sewage treatment: In sewage treatment plants, Roots blowers are used to add oxygen to the aeration tank, and the oil standard ensures that the equipment operates under appropriate lubrication conditions and extends its service life.

Food processing: Roots blowers used in the food industry require oil-free compression and low-noise operation, but for non-contact parts, oil indicators still provide the necessary monitoring functions.Aquaculture: If Roots blowers used in aeration systems are located close to residential areas, an oil mark is required to ensure stable operation of the system and ensure the safety of operators.

Other applications: including but not limited to various gas treatment tasks in power production, mining and metallurgy.