Product

Roots blower sound insulation cover

Roots blower sound insulation cover is an auxiliary equipment specially designed to reduce the noise generated by Roots blower during operation. It effectively blocks and absorbs noise by surrounding or partially surrounding the blower and its supporting systems (such as motors, pipes, etc.), thereby reducing the impact on the surrounding environment. This type of acoustic enclosure is particularly important in industrial settings, as many factories are located near residential areas or have strict sound pollution control standards.

Principle

The working principle of the soundproof cover is based on the principle of acoustics, which mainly includes the following points: Barrier effect: blocking the direct propagation sound path through physical barriers, sealing most noise sources.

Sound absorption and noise reduction: Use internal sound-absorbing materials to absorb sound energy in the high-frequency and mid-frequency ranges and convert it into heat energy for dissipation.

Damping and vibration reduction: For low-frequency noise, the damping effect provided by sound insulation panels and other structural components is relied on to suppress vibration transmission, thereby achieving the purpose of noise reduction.

Ventilation and silencing: For the intake and exhaust openings that must be retained, special mufflers can be installed to ensure gas circulation and significantly reduce the noise at the intake and exhaust openings.

Parameter

Size: customized according to specific applications

Noise reduction amount: Noise reduction effect of about 15 to 30 decibels (A)

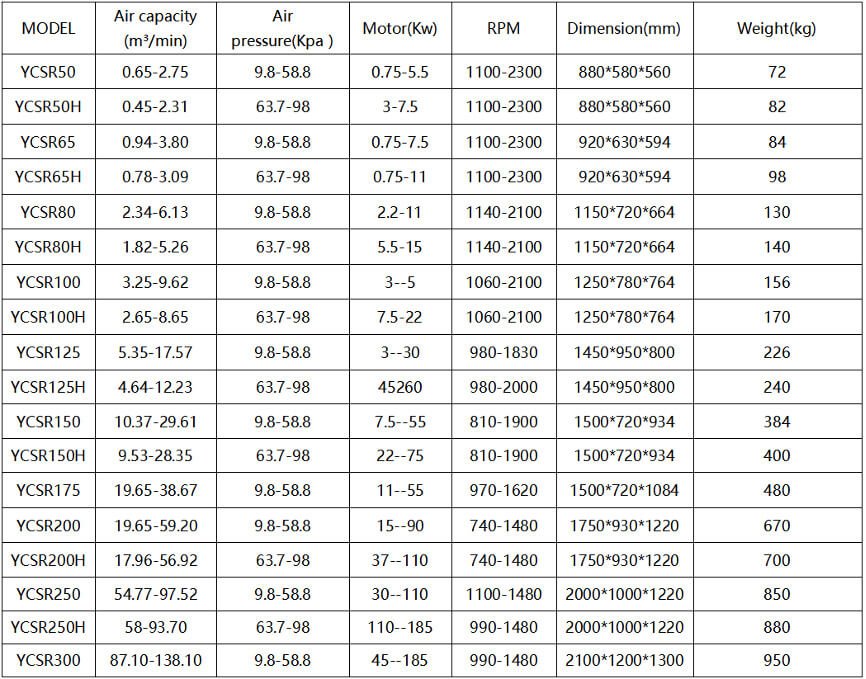

Temperature adaptability: high temperature resistance Single fuel tank: YCSR-(50/65/80/100/125/150/175/200/250/300)

High-pressure double fuel tank: YCSR-(80/100/125/150/200/250/300)H

Intensive: YCSR-MJ(50/65/80/100/125/150/175/200/250)

Roots vacuum pump: YCSR-(80/100/125/150/200/250/300)V

Features and Advantages

Significant noise reduction: The most intuitive advantage is that it greatly reduces the noise generated during the operation of the Roots blower and improves the quality of the working environment.

Easy to install: Modular structure facilitates on-site assembly, reducing construction time and cost.

Does not affect operation: The excellent sound insulation cover design will not hinder daily maintenance and inspection work, and all interfaces and observation windows can be easily accessed.

Beautiful and elegant: In addition to functionality, modern soundproof enclosures also focus on appearance design to make them more in line with the overall factory layout requirements.

Environmental protection and energy saving: By reducing unnecessary noise emissions, it helps enterprises comply with environmental regulations and also reduces energy consumption. Usage Scenarios

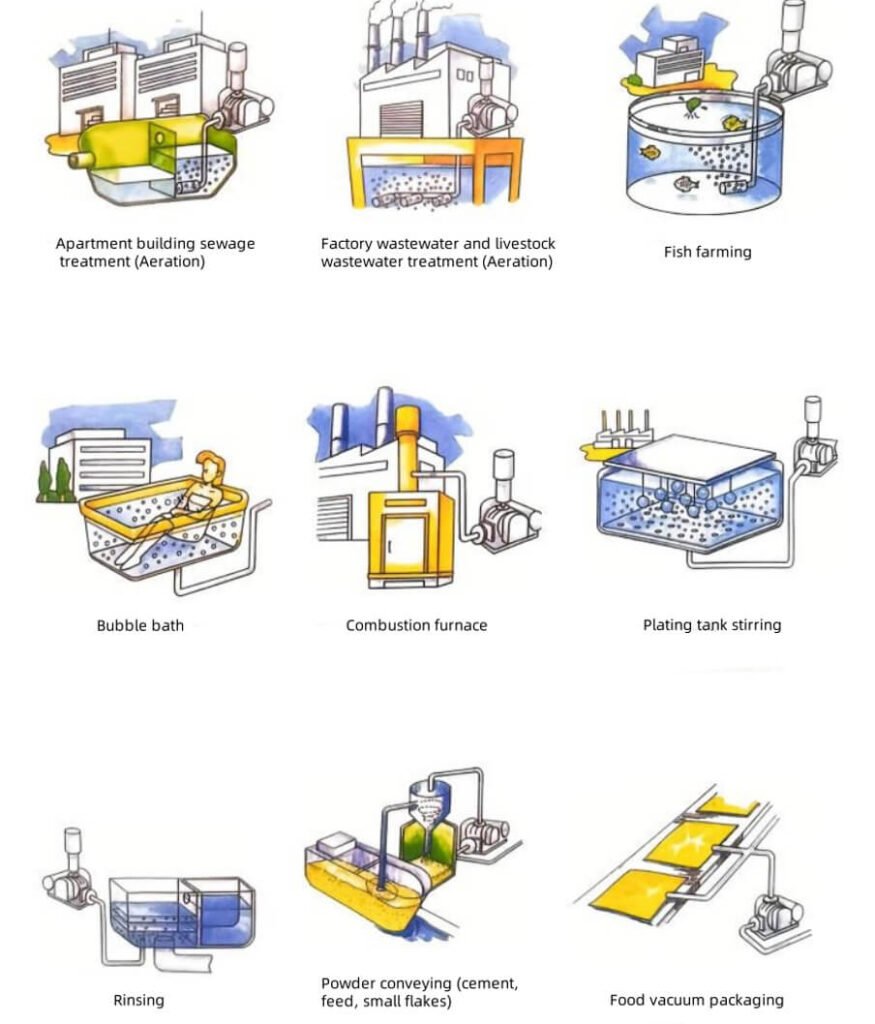

Roots blower sound insulation cover is widely used in many industries due to its excellent noise reduction effect, and is especially suitable for the following application scenarios: Industrial manufacturing: such as steel plants, cement plants, chemical plants, etc. In these places, Roots blowers are usually used for tasks such as gas transportation and waste gas treatment. Their operation is noisy and requires effective sound insulation measures.

Sewage treatment: In sewage treatment plants, Roots blowers are used to increase oxygen in aeration tanks, and soundproof covers can help maintain a quiet environment in the surrounding area.

Food Processing: Roots blowers used in the food industry require oil-free compression and low-noise operation, and acoustic enclosures can provide the necessary noise reduction without sacrificing hygiene standards.

Aquaculture: Roots blowers used in aeration systems will require soundproof enclosures to mitigate noise disturbance if they are located close to residential areas.

Other applications: including but not limited to various gas treatment tasks in power production, mining and metallurgy.