Roots vacuum pump negative pressure air source

Roots vacuum pump is a variable displacement vacuum pump with two blade-shaped rotors that rotate synchronously in opposite directions. There is a small gap between the rotors and between the rotors and the inner wall of the pump casing without contact. It extracts gas by changing the volume in the pump chamber and creates a negative pressure environment, which is suitable for applications that require the removal of air or other gases from a closed space. When used as a negative pressure air source, Roots vacuum pumps are particularly suitable for use in pneumatic conveying systems, which can effectively suck in materials and transport them along pipelines to their destination.

Principle

The working principle of Roots vacuum pump relies on two figure-8-shaped rotors that rotate synchronously and counter-rotating. When the motor drives one of the rotors to rotate, the other rotor rotates synchronously through the gears in the gearbox. As the rotor rotates, gas is sucked into the space formed by the rotor and pump housing, and then as the rotor continues to rotate, the space is gradually closed and isolated from the air inlet. Then, this closed space is opened again and connected to the exhaust port. At this time, due to the high pressure on the exhaust side, some of the gas may briefly flow back into the closed space, but then as the rotor rotates further, these gases along with The newly entered gas is pushed out of the pump together. This process is repeated continuously, resulting in continuous gas suction.

For some types of Roots vacuum pumps, in order to be able to operate at higher inlet pressures, special cooling mechanisms or relief valves are used to prevent overheating and overloading problems. For example, in an air-cooled Roots vacuum pump, part of the gas flowing out from the outlet flange passes through the cooler and then returns to the suction chamber. In this way, heat is taken away and the pump can operate stably at close to atmospheric pressure.

Parameter

Single fuel tank: YCSR-(50/65/80/100/125/150/175/200/250/300)

High-pressure double fuel tank: YCSR-(80/100/125/150/200/250/300)H

Intensive: YCSR-MJ(50/65/80/100/125/150/175/200/250)

Roots vacuum pump: YCSR-(80/100/125/150/200/250/300)V | MODEL | Air capacity (m³/min) | Air pressure (Kpa ) | Motor (Kw) | RPM | Dimension (mm) | Weight (kg) |

| YCSR80 | 2.34-6.13 | 9.8-58.8 | 2.2-11 | 1140-2100 | 1150*720*664 | 130 |

| YCSR100 | 3.25-9.62 | 9.8-58.8 | 3–5 | 1060-2100 | 1250*780*764 | 156 |

| YCSR125 | 5.35-17.57 | 9.8-58.8 | 3–30 | 980-1830 | 1450*950*800 | 226 |

| YCSR150 | 10.37-29.61 | 9.8-58.8 | 7.5–55 | 810-1900 | 1500*720*934 | 384 |

| YCSR200 | 19.65-59.20 | 9.8-58.8 | 15–90 | 740-1480 | 1750*930*1220 | 670 |

| YCSR250 | 54.77-97.52 | 9.8-58.8 | 30–110 | 1100-1480 | 2000*1000*1220 | 850 |

| YCSR300 | 87.10-138.10 | 9.8-58.8 | 45–185 | 990-1480 | 2100*1200*1300 | 950 |

Features and Advantages

- Quick start: able to establish the required vacuum conditions in a short time.

- Oil-free operation: There is no lubricating oil in the pump chamber, which avoids the risk of contamination. It is especially suitable for processes that require high gas purity.

- Compact design: Small footprint and easy to integrate into existing production lines.

- Low noise and vibration: Thanks to the good dynamic balance design, it can remain quiet and stable even at high speeds.

- High efficiency and energy saving: small mechanical friction loss and low maintenance cost.

- Strong adaptability: not only limited to dry gases, but also gases containing trace amounts of moisture or particulate matter.

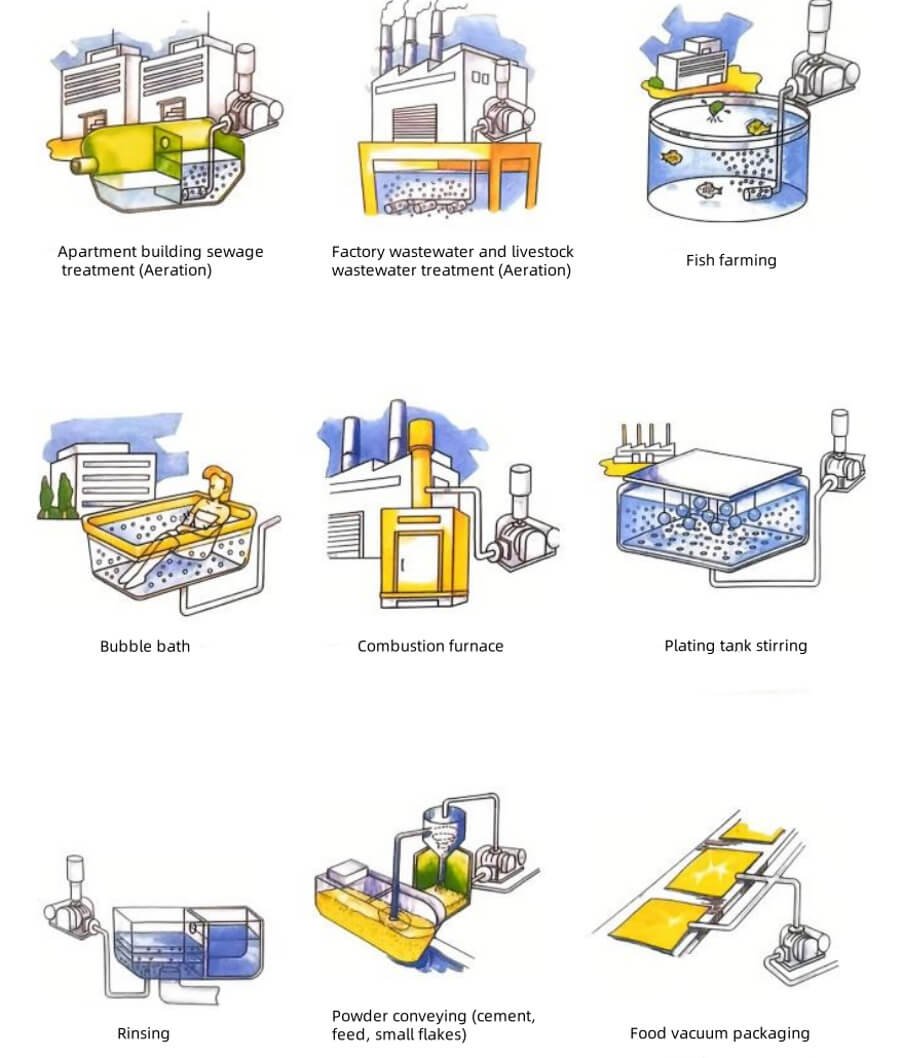

Usage Scenarios

Roots vacuum pumps are widely used in many industries due to their unique performance characteristics, especially in pneumatic conveying. The following are several typical usage scenarios: