Product

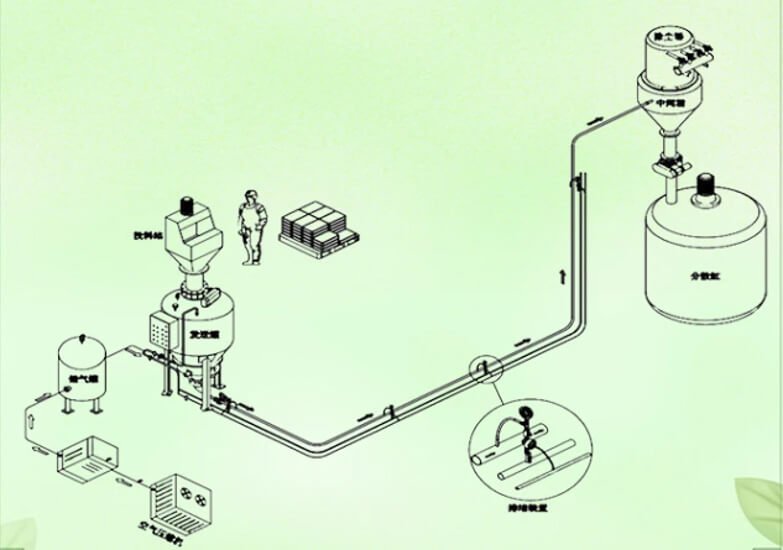

bunker pump

It is a key equipment in the pneumatic conveying system used to intermittently transport powder or granular materials from one location to another. It achieves efficient material transmission through three stages of periodic filling, pressurization and discharge, and is especially suitable for long-distance, high-lift material transportation tasks. The design of the silo pump allows it to handle various types of dry bulk materials and adapt to different conveying conditions.

Principle

Charging stage: The bin pump is in a low-pressure state, the feed valve is opened, and materials enter the bin pump through gravity or auxiliary equipment (such as screw feeder). When the material reaches the preset amount, close the feed valve and prepare to enter the next stage.

Pressurization stage: The air inlet valve opens, and compressed air or other gases are injected into the warehouse pump, causing the pressure in the warehouse pump to gradually increase to the set value. As the pressure increases, the material is compacted and forms columns with a certain density.

Discharging stage: The discharge valve is opened, and the high-pressure gas pushes the materials to move along the conveying pipeline until they are all discharged. After the discharge is completed, the discharge valve is closed and the warehouse pump returns to the initial low-pressure state to prepare for the next filling.

Purge stage (optional): In order to ensure that the pipeline is unobstructed, sometimes a short purge is performed after discharging to remove the material remaining in the pipeline.

Parameter

| Material | Q345R |

| work pressure | 0.1-0.6MpaMPa |

| Conveying medium | Air |

| Whether to support customization | yes |

| Transport items | Fly ash, cement and other powder and granular materials |

| Conveying capacity | 3-150t/h |

| Applicable fields | Cement, energy, chemical industry, etc. |

| Conveying distance | <2000m |

| Pressure bearing capacity | 1mpa |

| Conveying height | <30m |

| Use temperature | Minus 20-500℃ |

| Volume | 0.3-10m³ |

Features and Advantages

High efficiency and energy saving: Using compressed air as the power source reduces the number of mechanical transmission components and reduces energy consumption.

Compact structure: The overall design is simple and compact, easy to install and maintain, and saves space.

Strong adaptability: It can handle various types of materials and is not affected by the humidity and viscosity of the materials.

High degree of automation: Cooperating with the PLC control system, it can achieve fully automatic operation and reduce manual intervention.

Safe and reliable: equipped with multiple protection mechanisms, such as overload protection, short circuit protection, etc., to ensure the safety of personnel and equipment.

Easy to expand: Supports modular design to facilitate adding new functions or expanding production capacity later.

Good environmental performance: closed conveying avoids flying dust and reduces environmental pollution. Usage Scenarios

Silo pumps are widely used in all aspects of pneumatic conveying systems, especially where large amounts of powder or granular materials need to be transported over long distances and at high lifts.- Building materials

- Electrical facilities

- Chemical industry

- Mining

- Food processing industry

- Pharmaceutical industry

- Agriculture and feed processing